4.3PS – Pump Stand

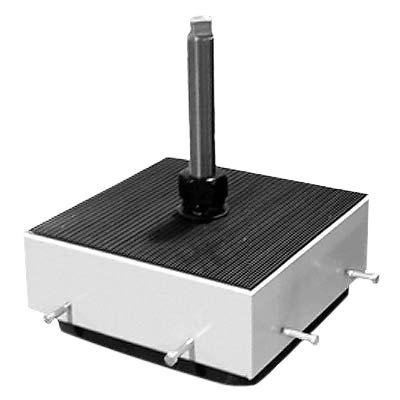

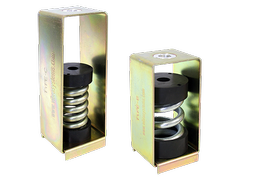

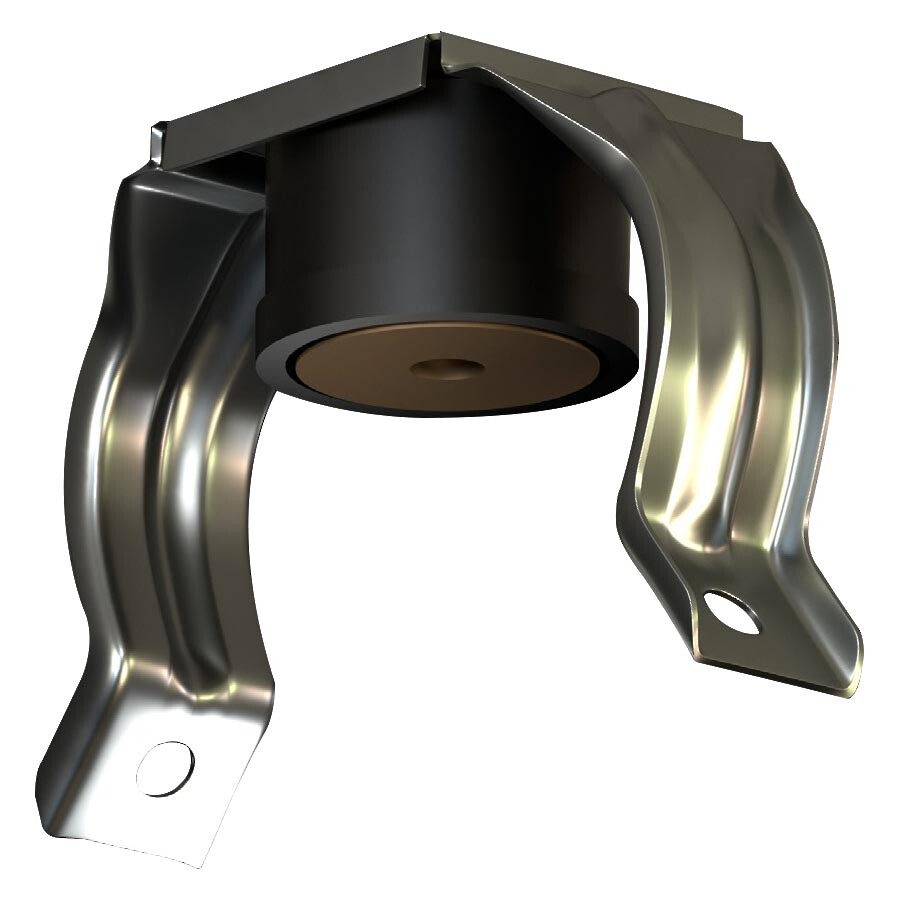

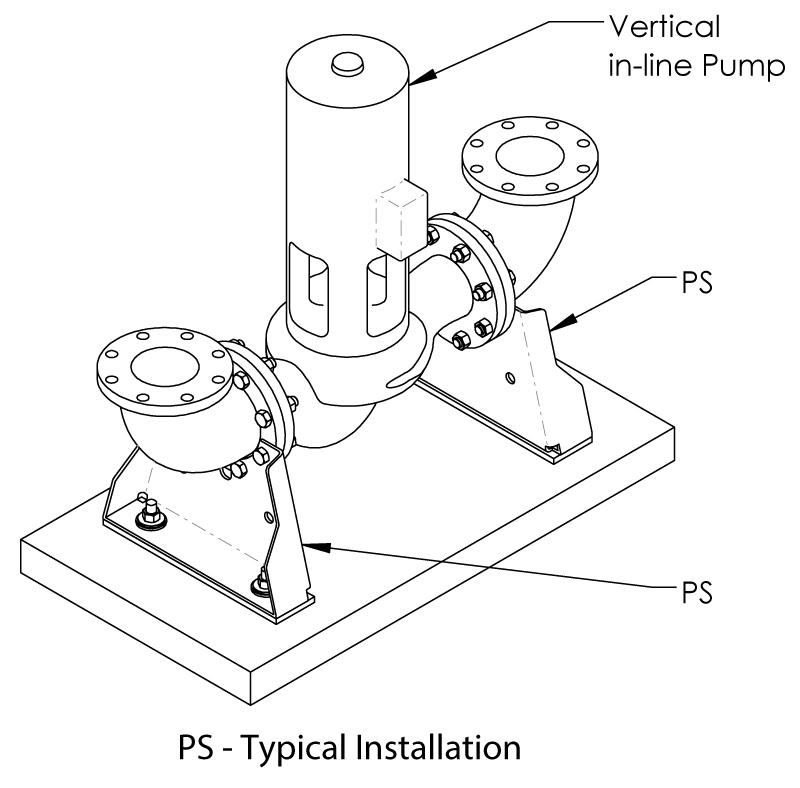

PS – Pump Stands are commonly used in the industry to give structural support to vertical in-line pumps while providing isolation from minor vibrations.

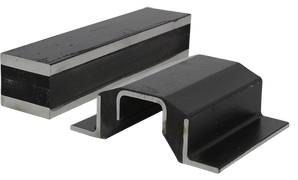

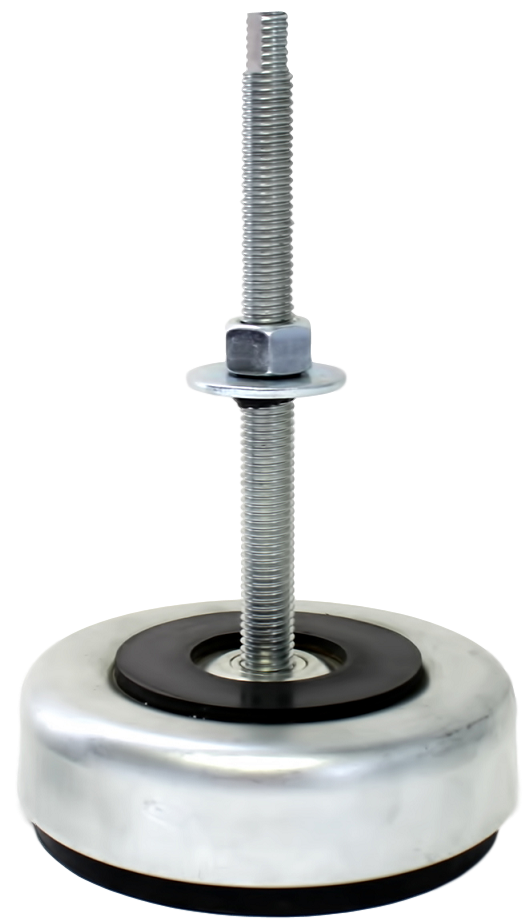

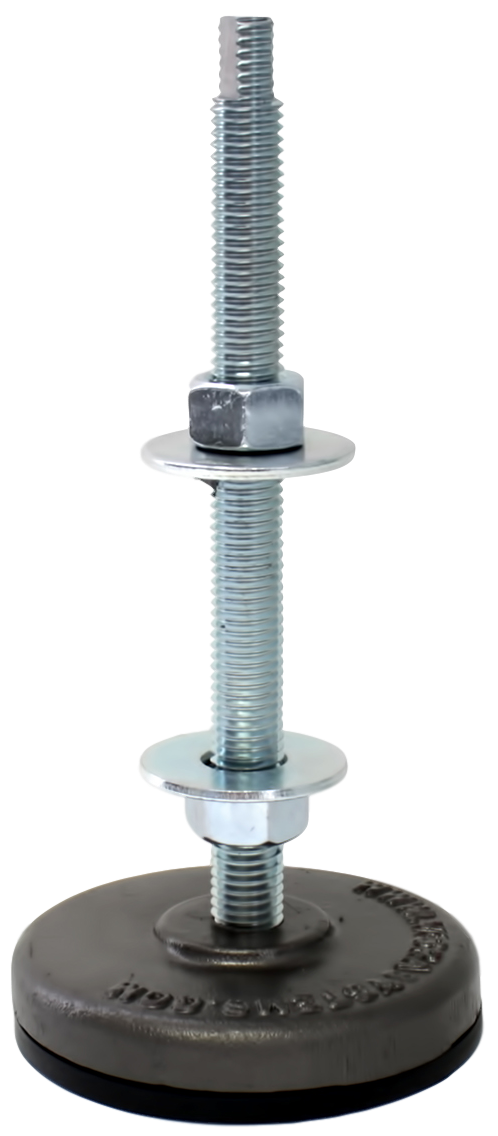

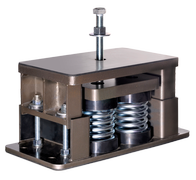

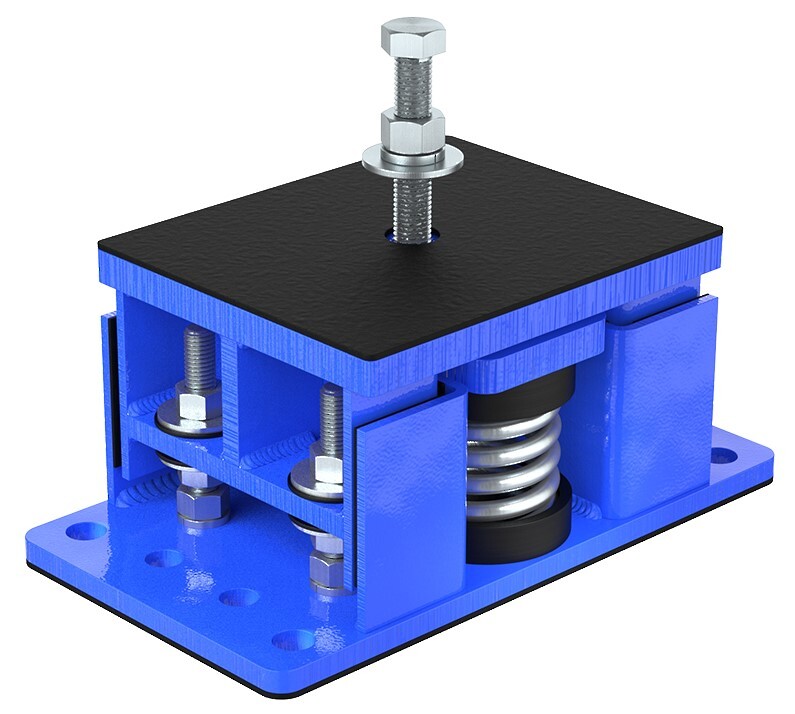

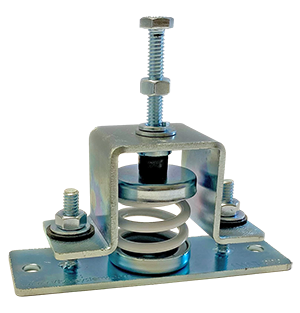

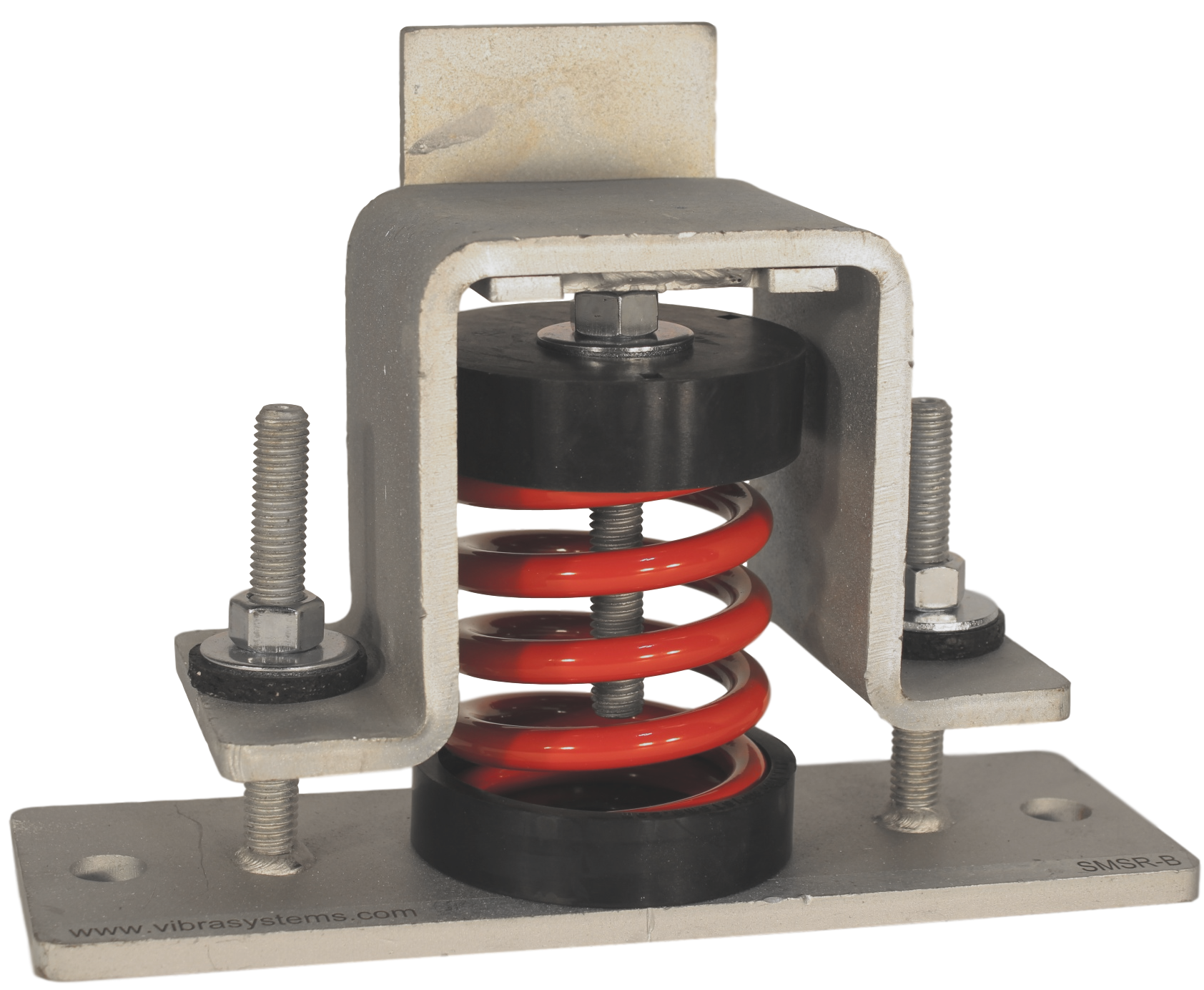

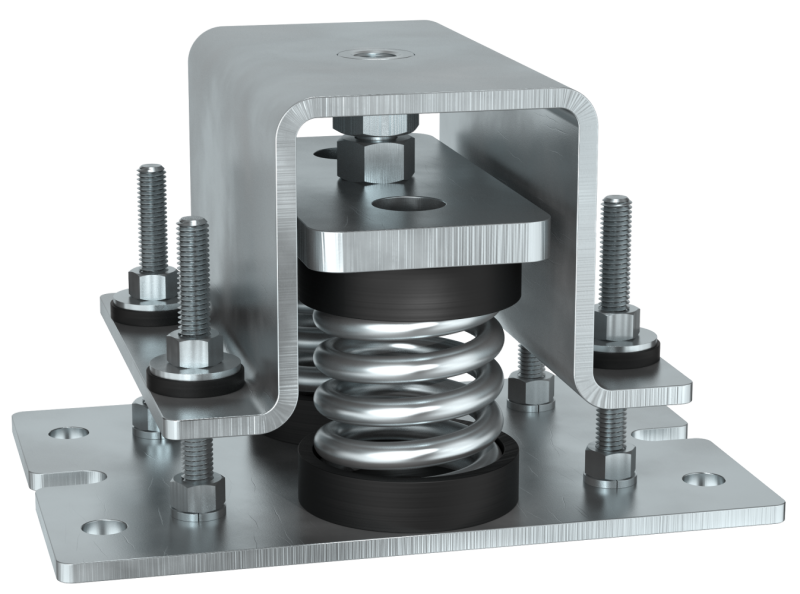

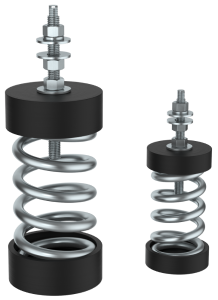

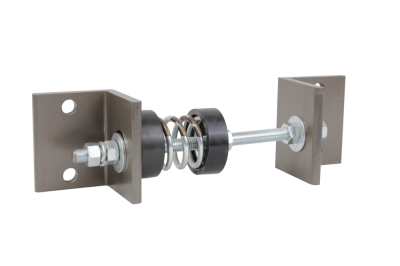

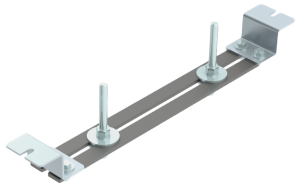

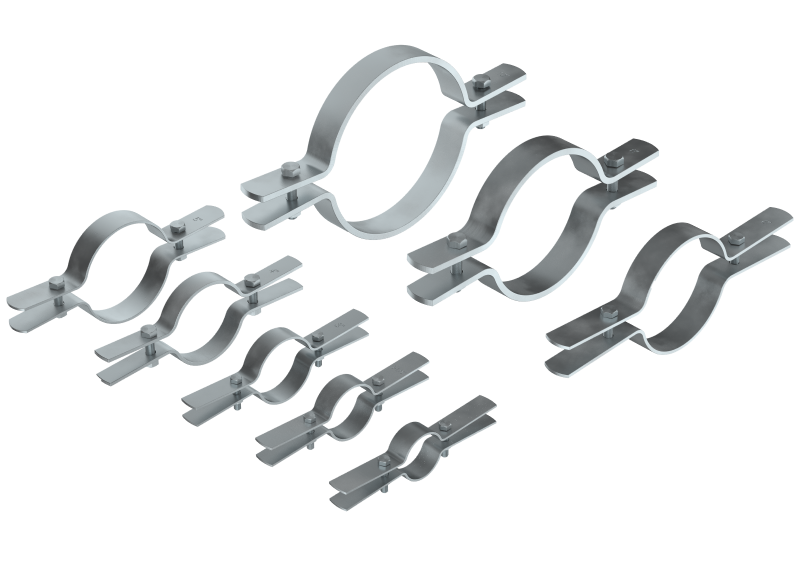

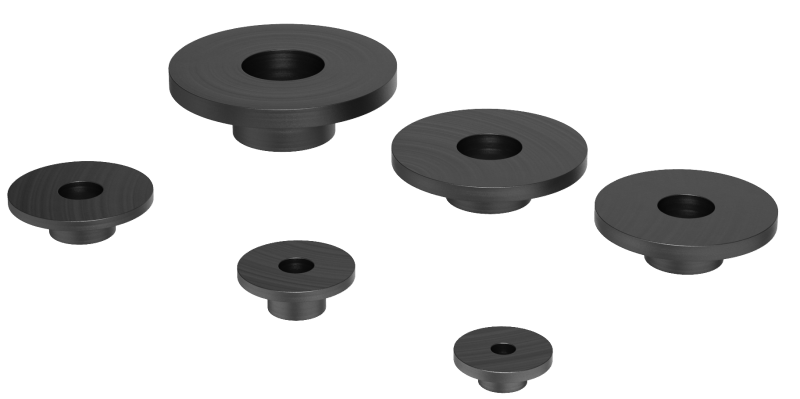

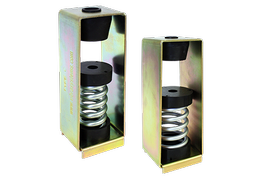

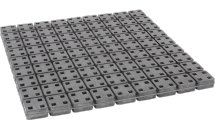

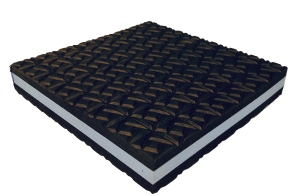

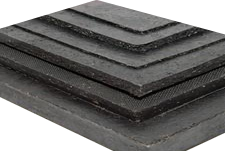

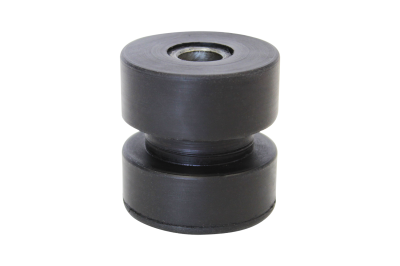

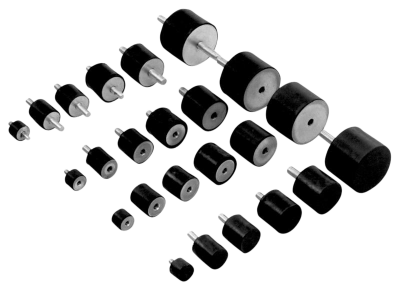

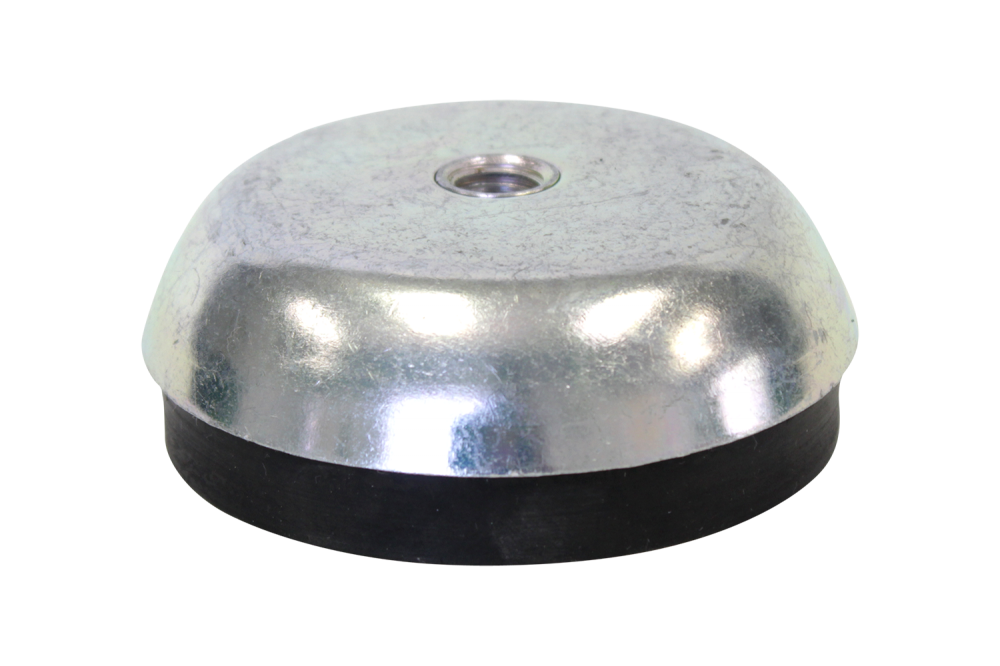

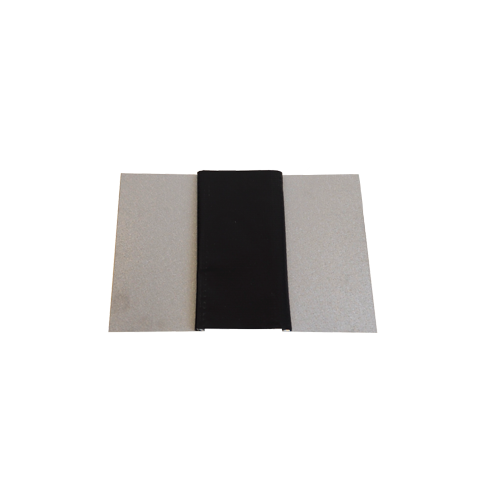

The new line of Vibrasystems’s Vertical in-line Pump Stand has a solid, heavy-duty welded reinforced steel frame, an elastomer bearing pad, and two bridge-bearing bushings. PS's frame is powder-coated for corrosion protection. The elastomer bearing pad provides excellent isolation from transferring vibrations to the pump stands. The bridge-bearing neoprene washer bushings isolate anchor bolts from the pump stand metal frame.

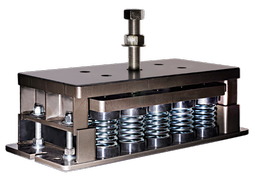

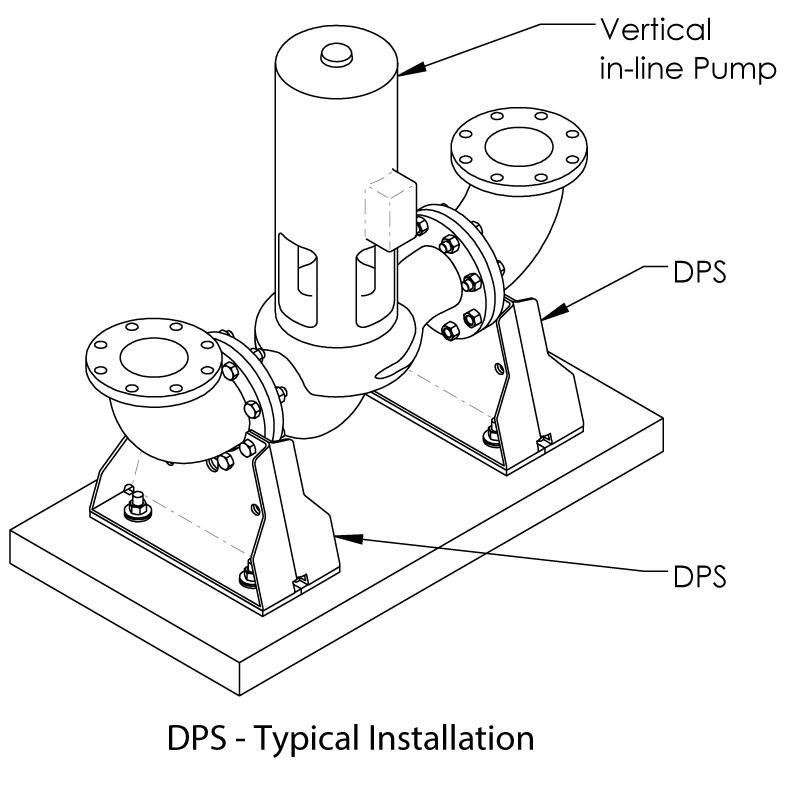

DPS – Double Pump Stand consists of two PS Pump Stands bolted together.

This installation is recommended for extra-heavy in-line vertical pumps where an increase in structural rigidity is required and for installation in seismic active zones.

Recommended for:

Vibrasystem’s Vertical in-line Pump Stands are designed for Vertical in-line pumps ranging from 1.5” to 12” pump flange size. Pump stands are designed with two hole patterns: one that matches the cast iron flange dimensions for ANSI Class 125, and another that matches the flange dimensions for ANSI Class 250. Double Pump Stands (DPS models) are recommended for extra-heavy vertical in-line pumps to increase stability and protect from seismic forces.

Features:

| Model | Pump's Flange Size (in) | Shipping Weight (lbs) | Price | Quantity | Total | |

|---|---|---|---|---|---|---|

| PS - Pump Stand (Class 125) | ||||||

| PS-1.5 | 1-1/2 | 10 | $204.00 USD |

| ||

| PS-2 | 2 | 10 | $204.00 USD |

| ||

| PS-2.5 | 2-1/2 | 10 | $204.00 USD |

| ||

| PS-3 | 3 | 12 | $216.00 USD |

| ||

| PS-4 | 4 | 22 | $234.00 USD |

| ||

| PS-5 | 5 | 22 | $234.00 USD |

| ||

| PS-6 | 6 | 38 | $264.00 USD |

| ||

| PS-8 | 8 | 38 | $288.00 USD |

| ||

| PS - Pump Stand (Class 250) | ||||||

| PS-2-250 | 2 | 14 | Inquire | |||

| PS-3-250 | 3 | 14 | Inquire | |||

| PS-4-250 | 4 | 32.5 | Inquire | |||

| PS-5-250 | 5 | 37.5 | Inquire | |||

| PS-6-250 | 6 | 37.5 | Inquire | |||

| PS-8-250 | 8 | 37.5 | Inquire | |||

| DPS - Double Pump Stand (Class 125) | ||||||

| DPS-1.5 | 1-1/2 | 20 | $408.00 USD |

| ||

| DPS-2 | 2 | 20 | $408.00 USD |

| ||

| DPS-2.5 | 2-1/2 | 20 | $408.00 USD |

| ||

| DPS-3 | 3 | 24 | $432.00 USD |

| ||

| DPS-4 | 4 | 44 | $468.00 USD |

| ||

| DPS-5 | 5 | 44 | $468.00 USD |

| ||

| DPS-6 | 6 | 76 | $528.00 USD |

| ||

| DPS-8 | 8 | 76 | $576.00 USD |

| ||

| DPS-10 | 10 | 80 | - | - | Inquire | |

| DPS-12 | 12 | 88 | - | - | Inquire | |

| DPS - Double Pump Stand (Class 250) | ||||||

| DPS-2-250 | 2 | 29 | Inquire | |||

| DPS-3-250 | 3 | 29 | Inquire | |||

| DPS-4-250 | 4 | 66 | Inquire | |||

| DPS-5-250 | 5 | 66 | Inquire | |||

| DPS-6-250 | 6 | 76 | Inquire | |||

| DPS-8-250 | 8 | 76 | Inquire | |||

Notes:

a) Advertised price is per piece. Two (2) Pump Stands (PS) per vertical in-line pump are recommended.

b) Pumps Stands for flanges sizes over 8" are available upon request.

c) Please see the submittal drawings and Installation Instructions for more information.

d) Pump Stand must be installed in pairs (see installation instructions).

Support and Stability: The primary purpose of a pump stand (PS) is to provide a stable and secure platform for the inline pump. This ensures that the pump remains steady during operations, preventing vibrations and misalignment that could lead to performance issues or damage.

Customization: Pump stands can be customized to accommodate different sizes and types of inline pumps. This might include adjustable brackets or mounts to secure the pump properly.

Material and Design: Pump stands can be made from various materials depending on the application and this will be a custom order. Common materials include stainless steel, carbon steel, or other corrosion-resistant materials, especially if the pump is used in environments where chemicals or other corrosive substances are present.

Base and Foundation: The base of the pump stand should be designed to provide stability and prevent any movement during pump operation. Adequate foundations might be required based on the pump's size, weight, and the nature of the fluid being pumped.

Piping and Connection: A pump stand for inline pumps may also include integrated piping and connections to facilitate the inlet and outlet connections of the pump to the existing pipeline.

Safety: Safety features such as guardrails, access platforms, and protective covers might be integrated into the pump stand design to ensure the safety of operators during maintenance and operation.

We apologise for the inconvenience but this product is currently unavailable online. Please contact us directly to place your order

Phone: 18005670785

Email: info@vibrasystems.com