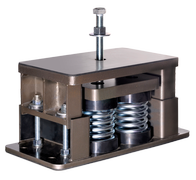

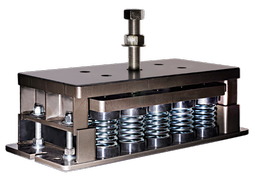

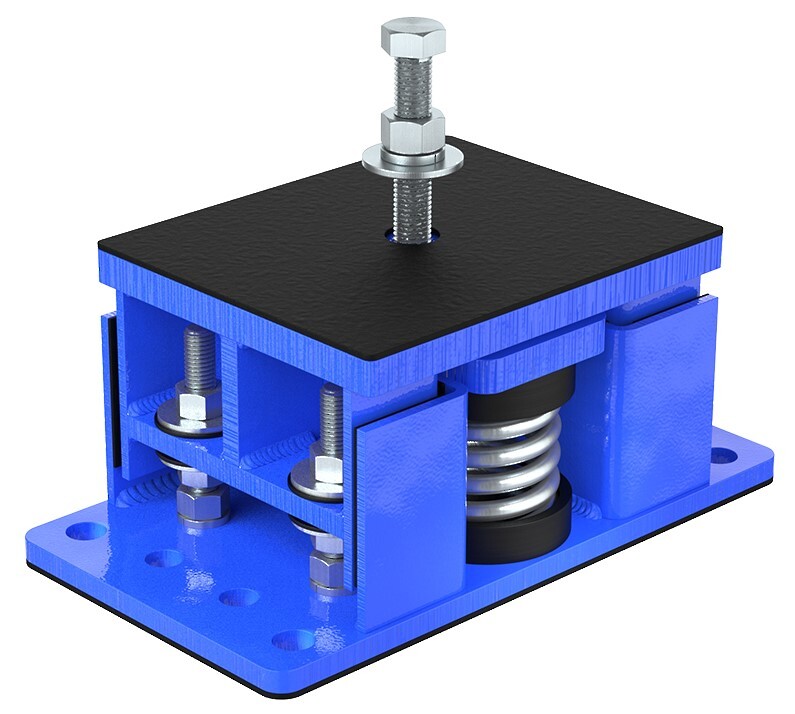

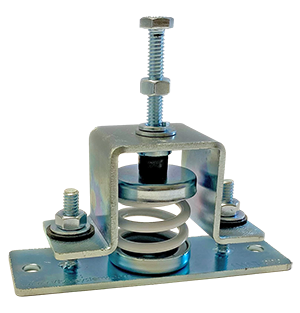

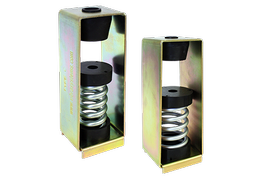

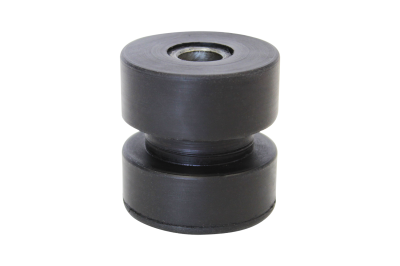

1.1VSCM - Engine/ Motor/ Marine Vibration Dampers

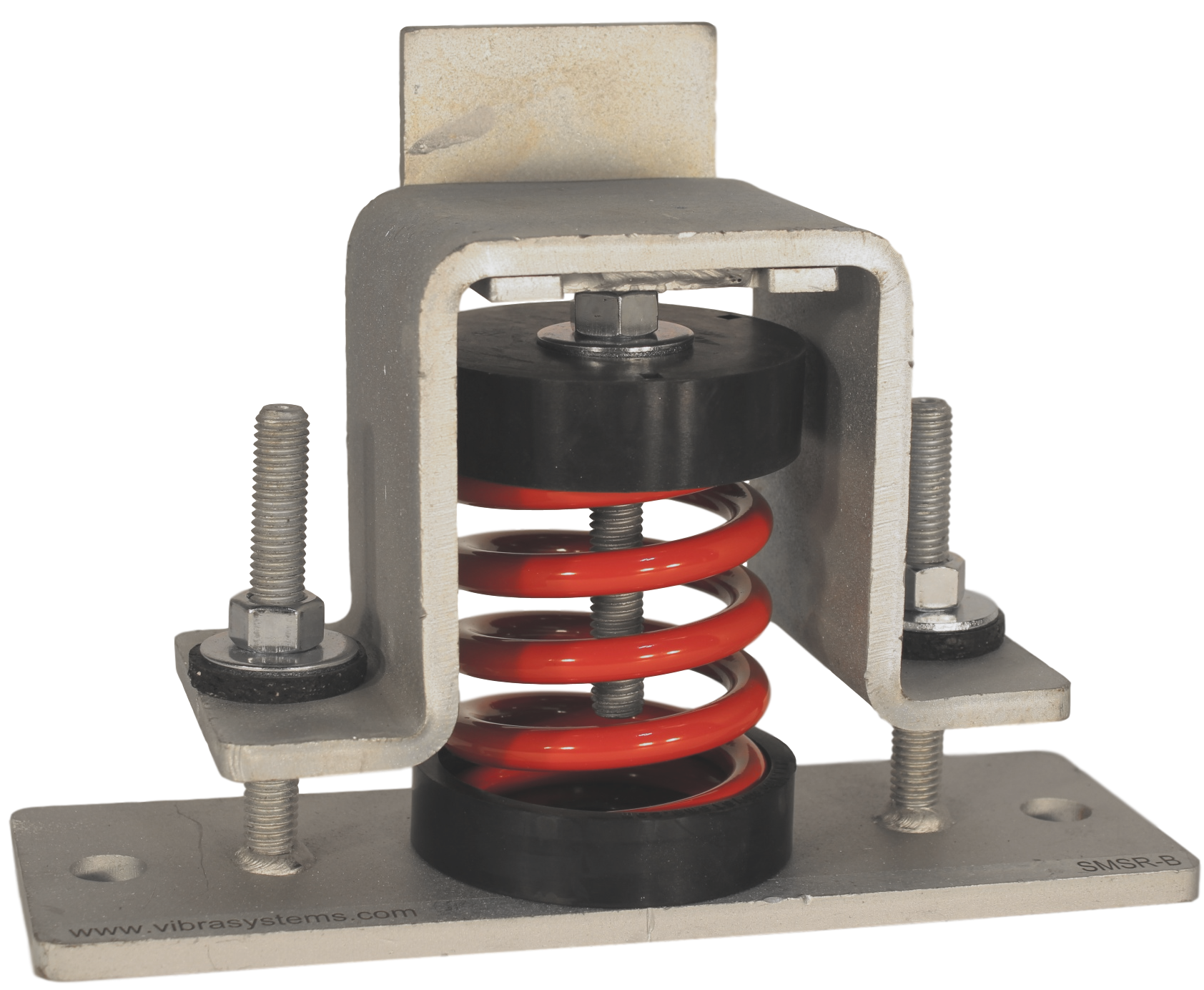

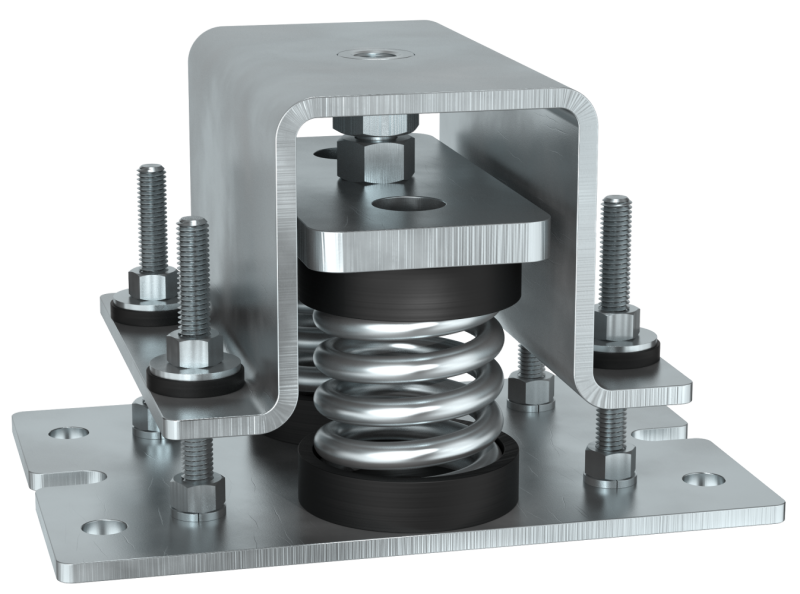

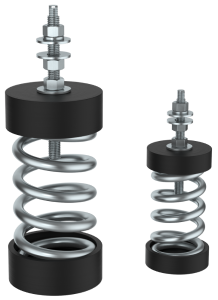

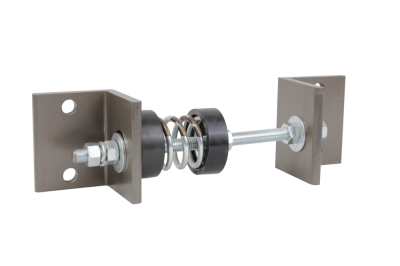

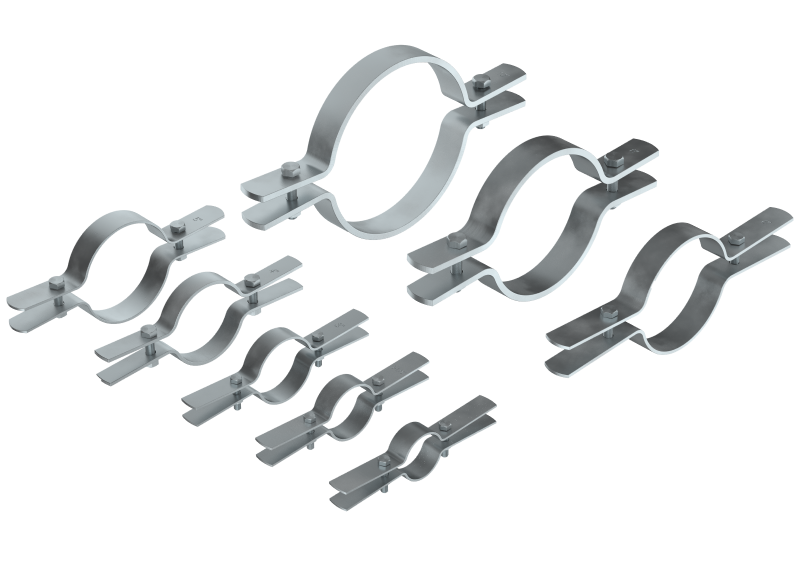

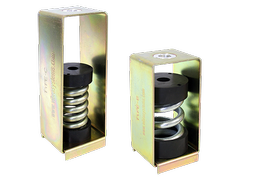

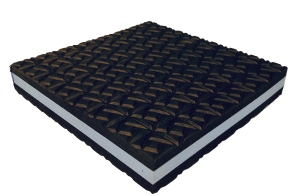

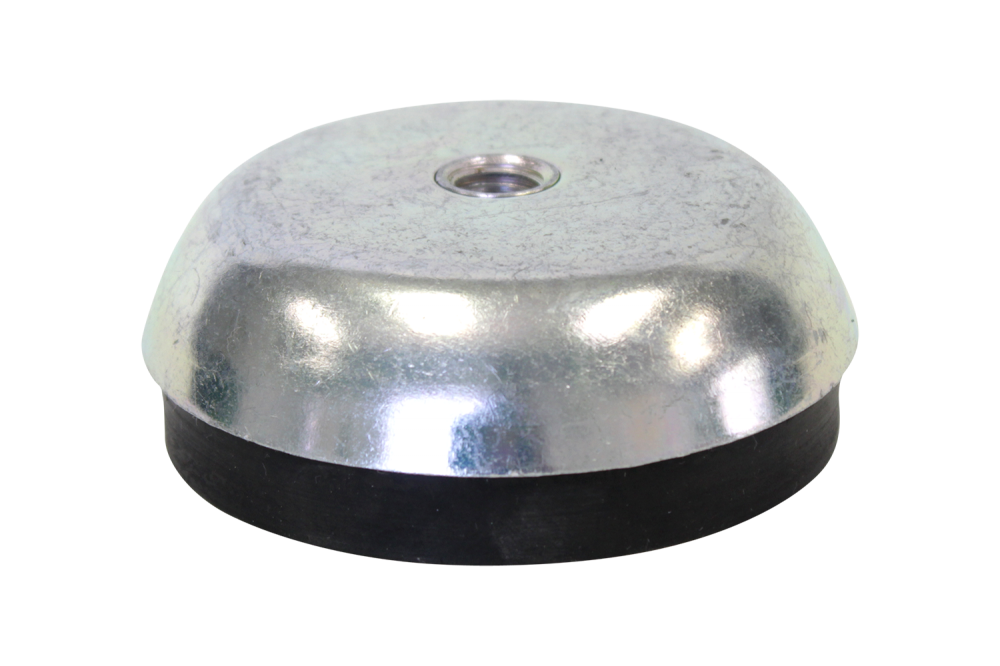

VSCM compression-shear cup/engine mounts provide excellent protection against vibration and shock.

Due to each mount's ability to isolate vertical and horizontal forces, they are used in a wide variety of industrial applications.

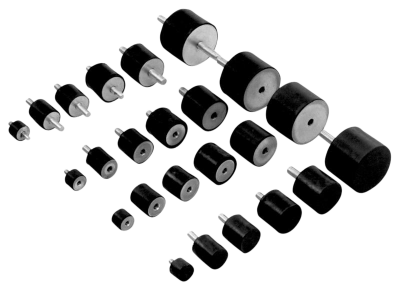

Recommended for:

Vibration isolation of industrial machinery, centrifuges, blowers, transformers, combustion engines, motors, marine and industrial diesel generator sets, pumps, HVAC, factory production equipment, and where anchoring is required.

Features:

A vibration isolation mounts that is also called vibration isolator or damper is designed to reduce or completely eliminate vibration from one component or structure to another. The primary use and purpose of these isolators is to extend logevity of the equipment without compromisimg safety and performance.

Key features of our VSCM engine, marine mounts are:

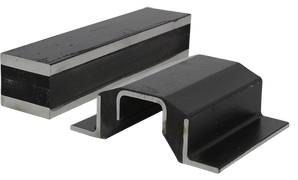

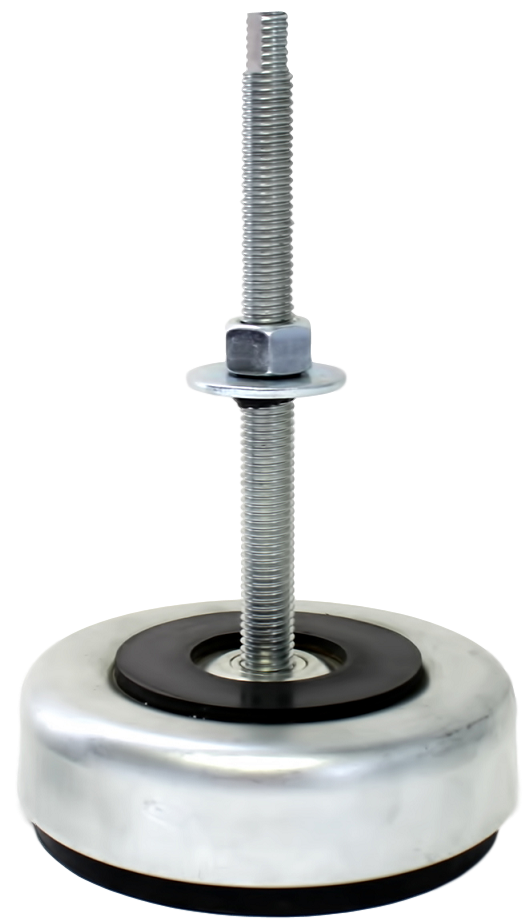

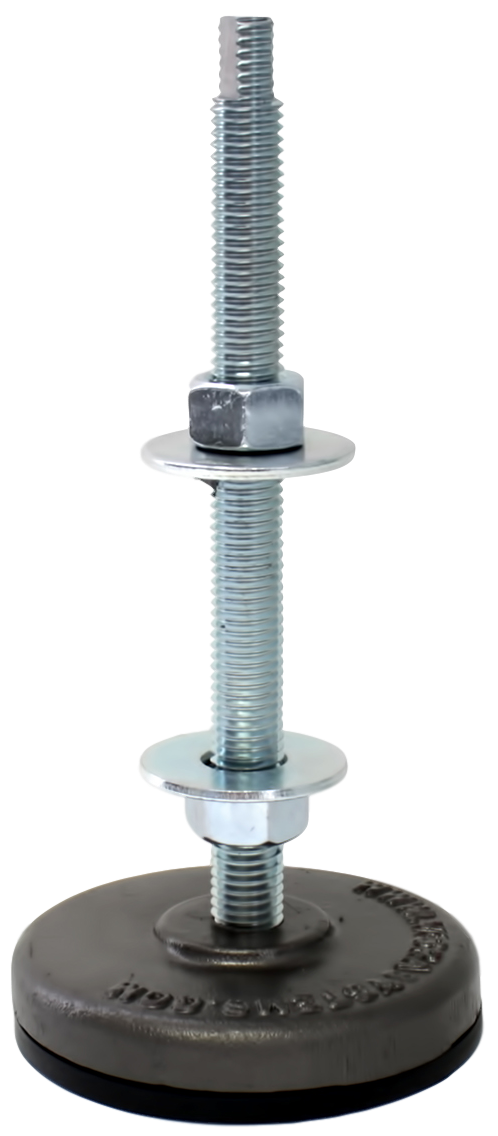

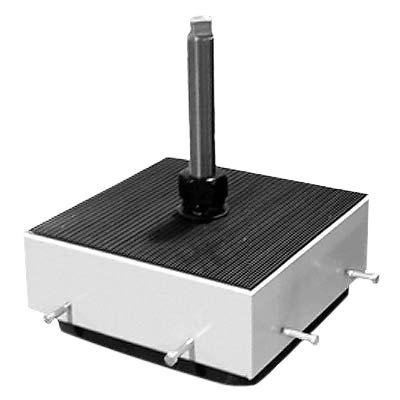

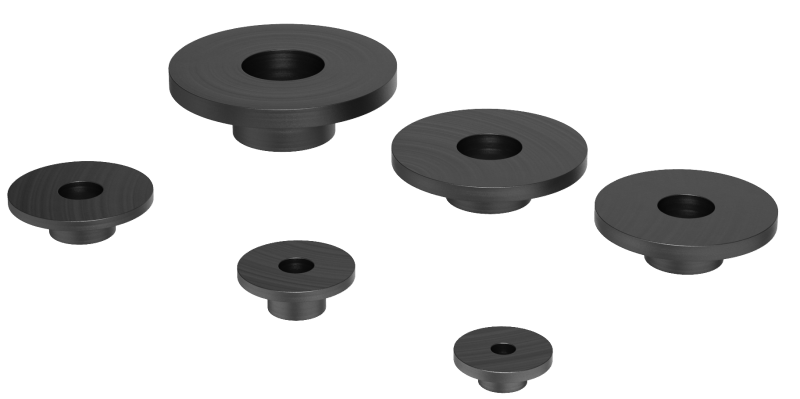

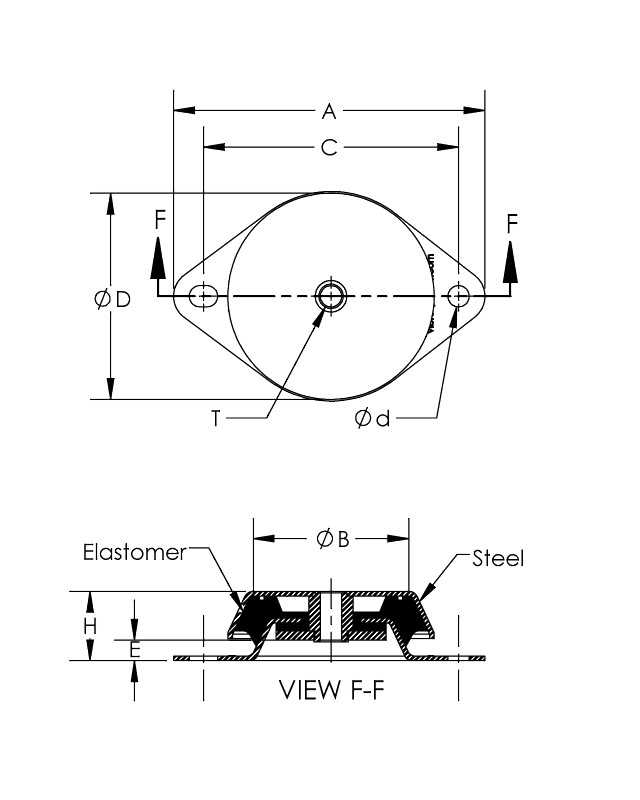

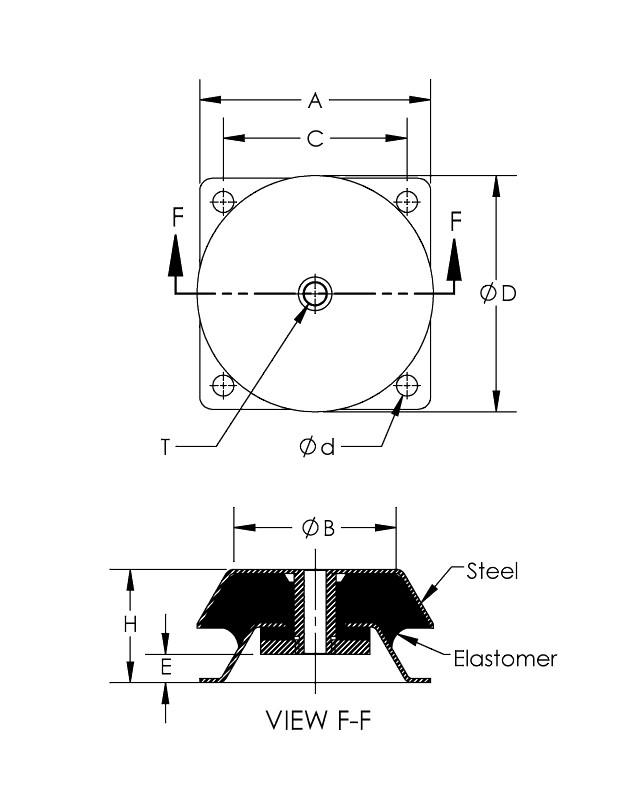

Inside elastomer made of Neoprene or EPDM rubber to provide elasticity and deflection for vibration isolation.

Top Metal Cup and Bottom Metal Plate for durability and protection from environmental destructions and excessive shaking. Vibrasystems Inc can produce these antivibration mounts in different type of materials as per customers' requirements.

Top bushing with threaded hole for easy installation and fastening of the equipment.

Bottom opening in the plate for securing the vibration isolator to the floor.

Unique shape of Vibrasystems Inc motor/engine/marine antivibration mounts is allowing to use them in the wide variety of mechanical equipment.

While choosing these isolator for installation under the motors following factors should be considered: motor's size, weight, operating speed, the criticality of vibration control, and the surrounding environment. In the complicated situation, it is essential to consult engineering of Vibrasystems team for free over the phone consultation before purchasing.

During the selection of our antivibration isolators for the engines it is important to conduct a dynamic analysis of the engine and its surroundings to identify vibration sources, resonant frequencies, and potential vulnerable spots. Ensure that the engine's rotating components are balanced correctly. Imbalancing can contribute to excessive vibrations. Regular inspection and calibration will help to detect issues with the vibration levels and prevent failures.

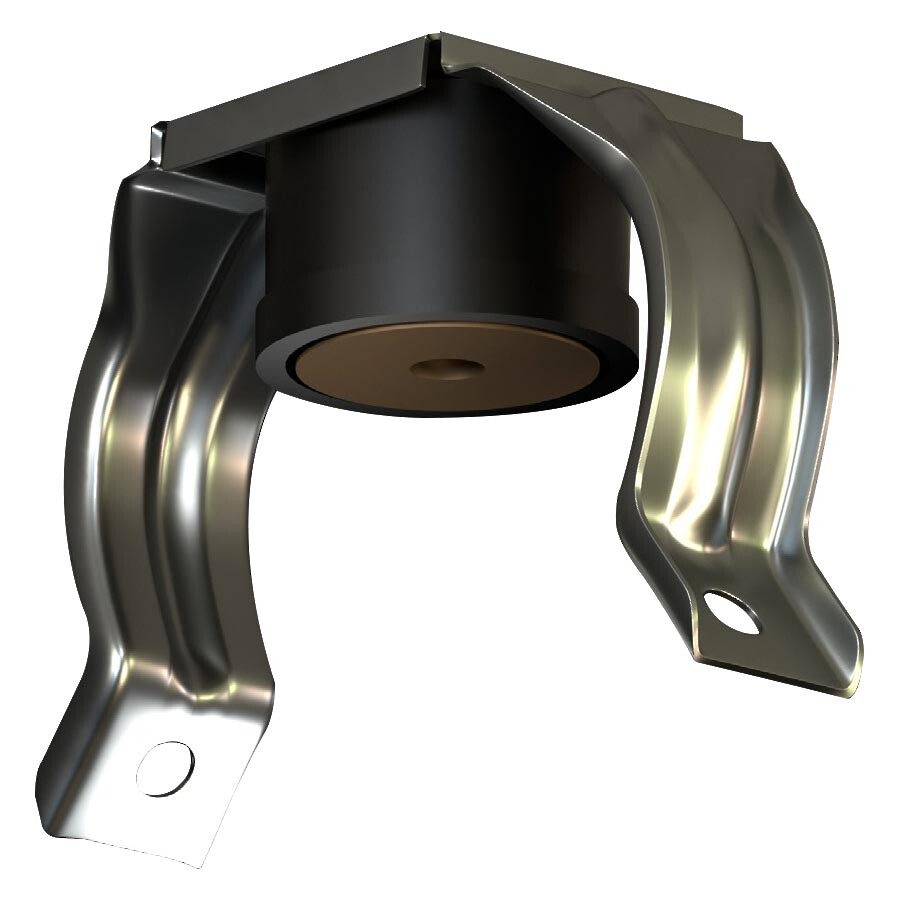

Vibrasystems Inc VSCM antivibration mounts are often being installed in marine applications for maintaining the integrity, performance, and safety of vessels and offshore structures. Properly designed and installed vibration isolation dampers can significally enhance the overall experience and longevity of marine systems. Stainless steel finish and EPDM rubber insert are core features of our CMSS type mounts for maritime industry.

Note: Shear load should not exceed 30% of Compression load.

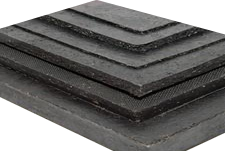

Optional Materials:

• For marine, offshore, and other corrosive environments, mounts are made of 316 L stainless steel and EPDM rubber compound.

• For food, pharmaceutical, and hygiene critical applications, mounts are made of 304 stainless steel and food grade rubber compounds.

• Contact VibraSystems Inc. technical department for optimal material selection.

We apologise for the inconvenience but this product is currently unavailable online. Please contact us directly to place your order

Phone: 18005670785

Email: info@vibrasystems.com