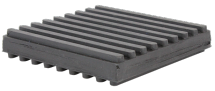

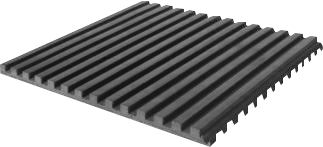

4.1WIB6 – Welded Inertia Base

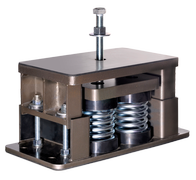

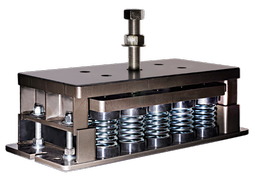

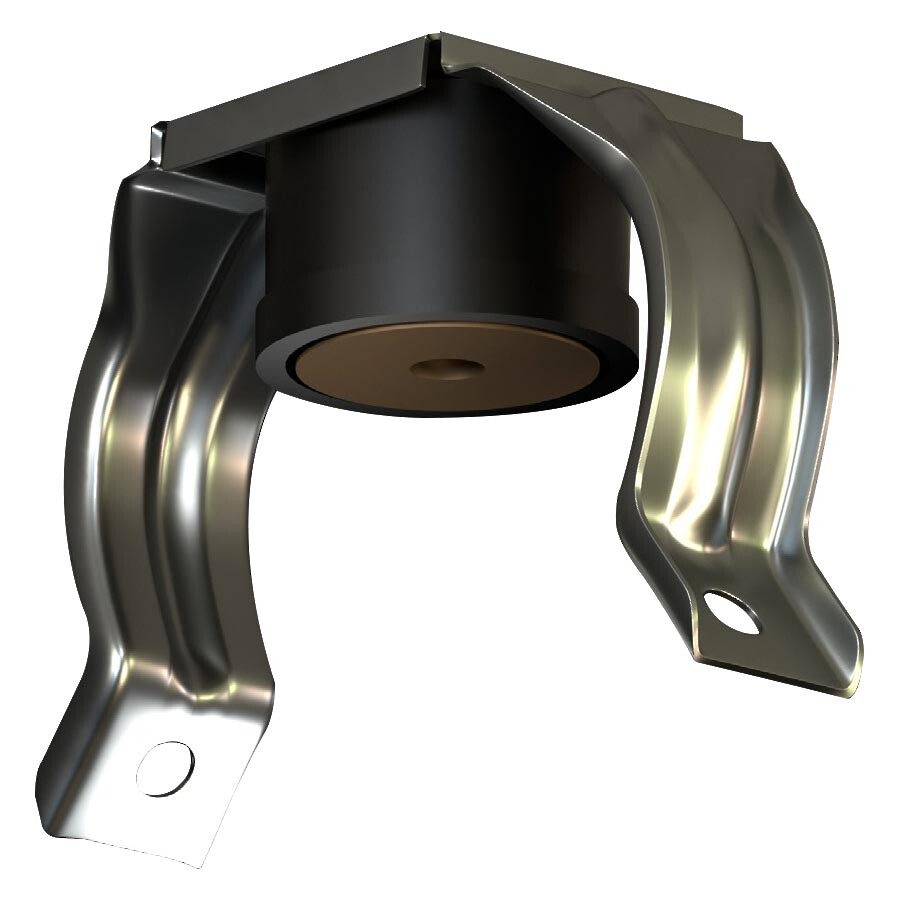

WIB6 - Heavy-duty Welded Inertia Bases are commonly used in the industry:

- to reduce the amplitude of mechanical vibrations.

- lower the center of gravity.

- lessen the equipment’s movement during operations.

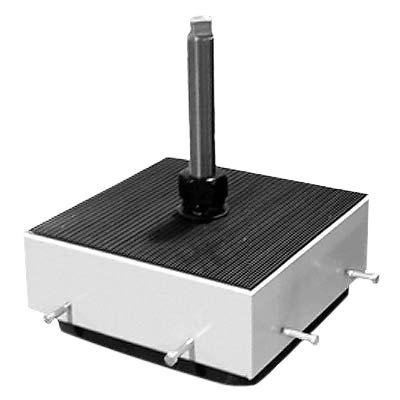

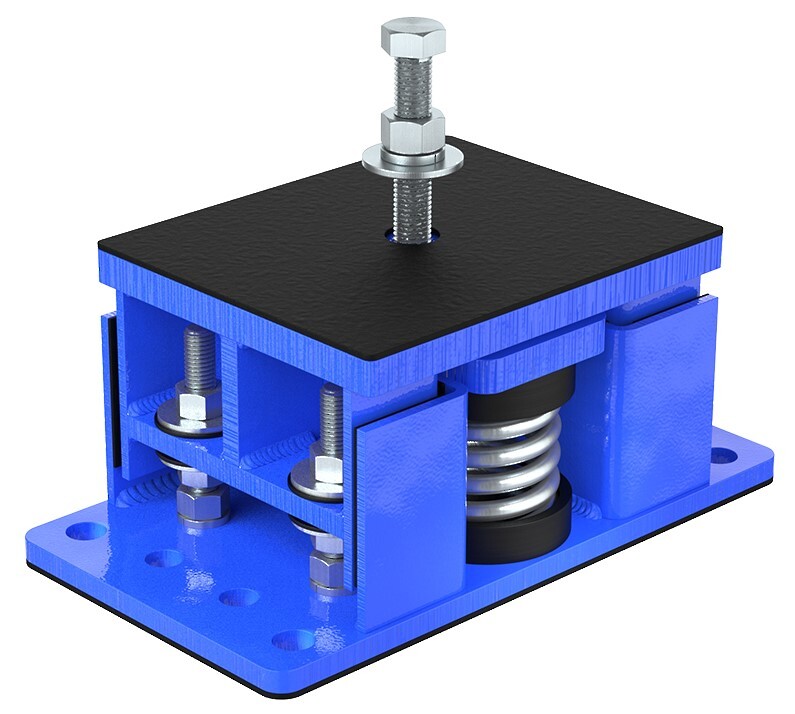

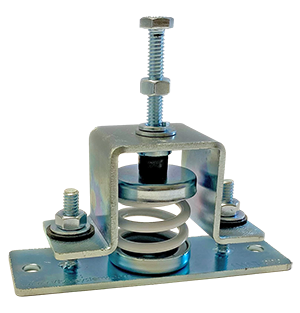

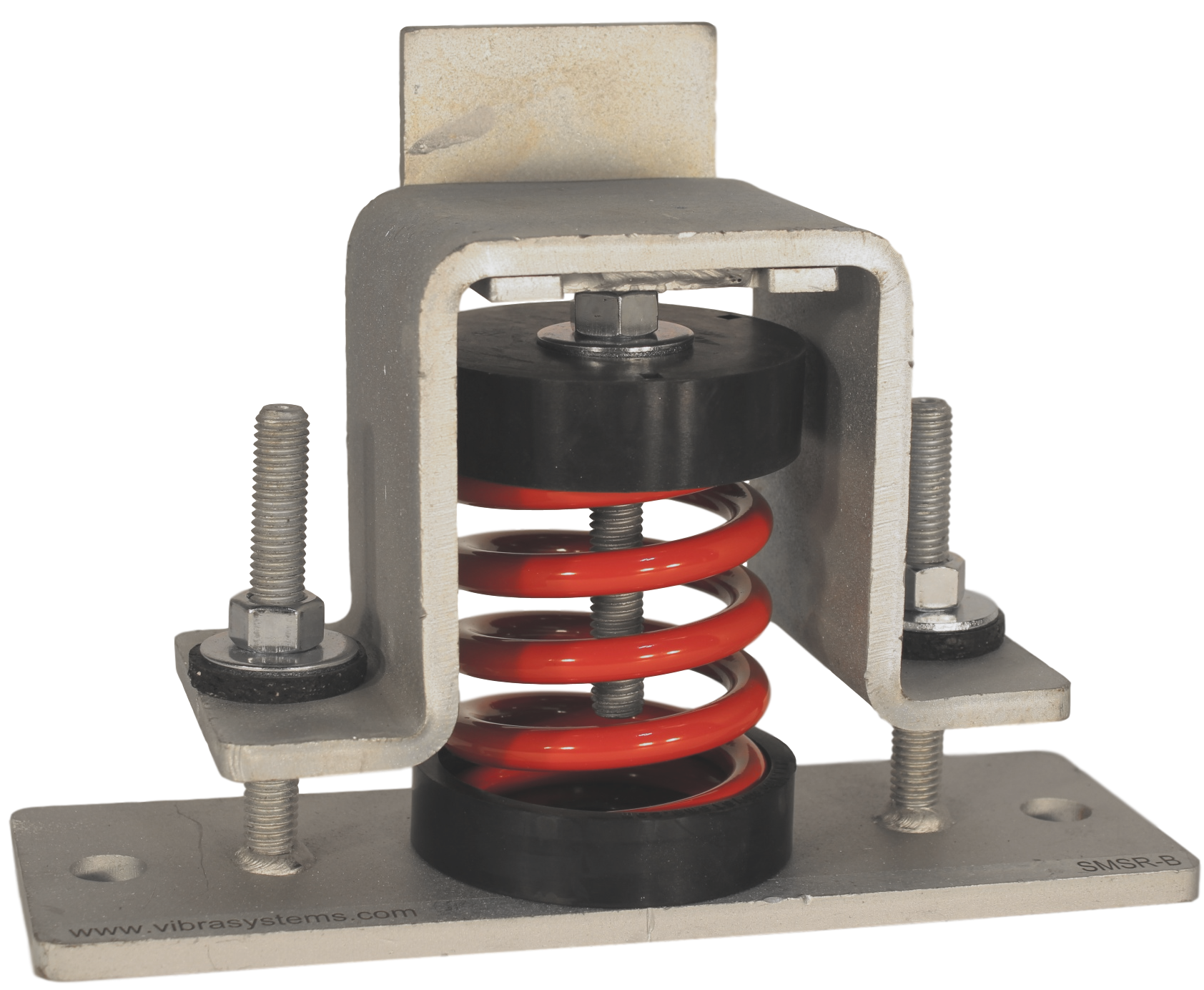

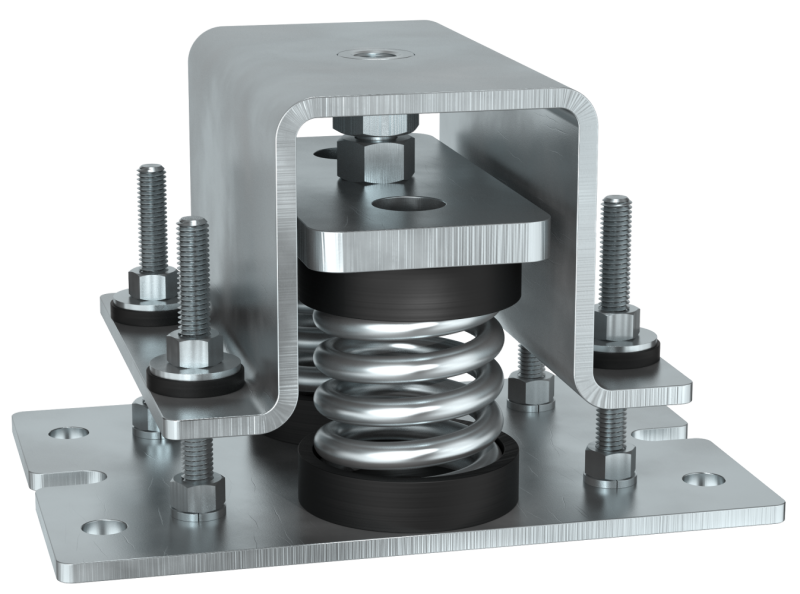

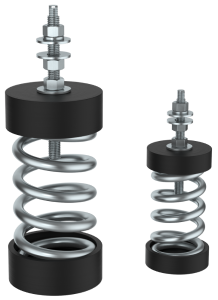

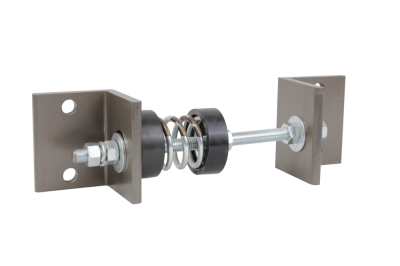

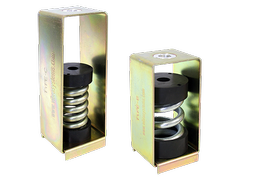

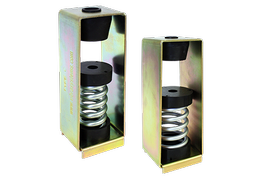

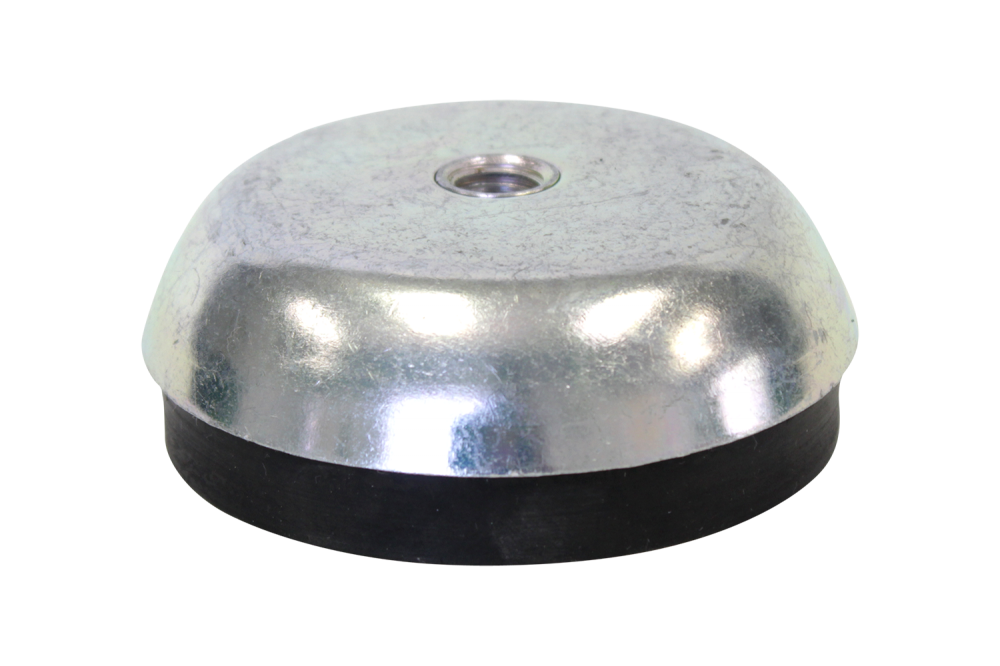

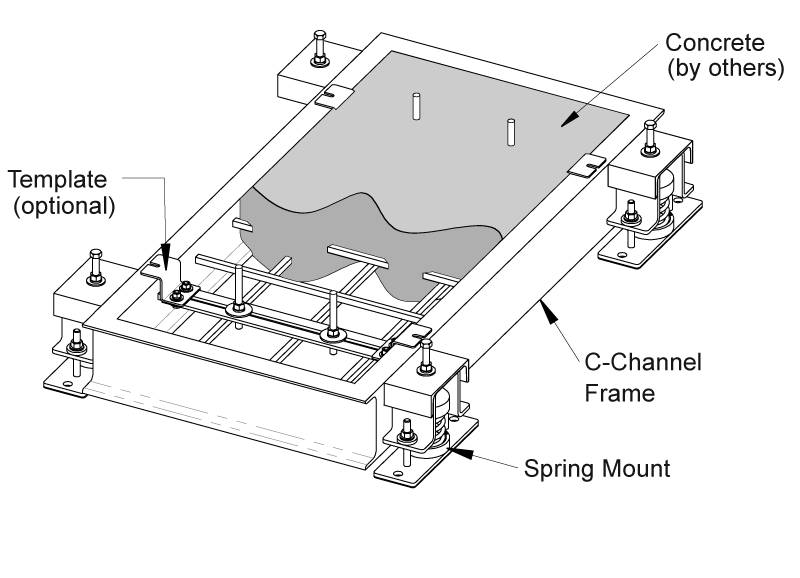

Metal Welded Inertia Bases, when filled with concrete and supported by Vibrasystems’ spring mounts, provides excellent vibration isolation.

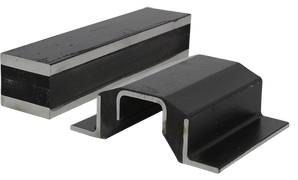

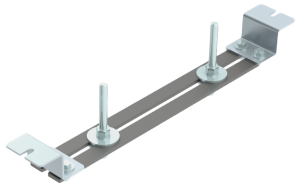

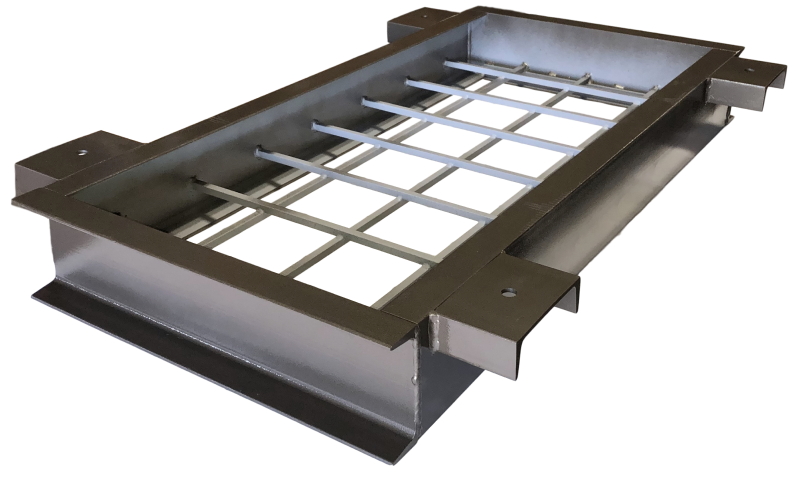

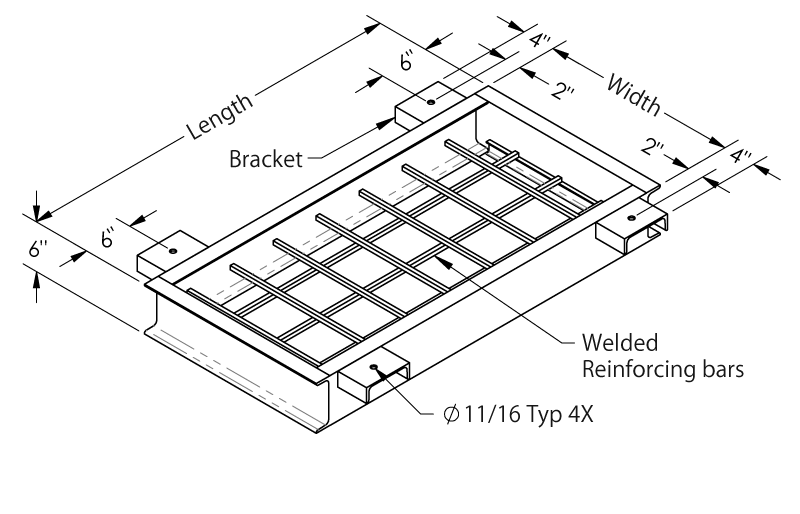

WIB6 - Welded Inertia Bases are designed according to ASHRAE guidelines. Made from structural steel C Channels and reinforced with welded steel square bars each WIB6 has welded brackets to install spring mounts under them. Welded Inertia Bases are finished with a rustproof primer and a topcoat paint.

Recommended for:

Provide vibration isolation and stabilize HVAC equipment such as air compressors, vacuum pumps, close-coupled pumps, inline pumps, end suction pumps, double suction pumps, package pump systems, axial fans, plenum fans, centrifugal fans, engine-driven generators, packaged Air Handler Unit, packaged Air Conditioner Unit, industrial centrifuges, etc.

Features:

| Model | Dimensions in inches (in) | Approximate Weight in Pounds (lbs) | Price | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | Width (in) | Length (in) | Height (in) | Frame (lbs) | Concrete (lbs) | Frame + Concrete (lbs) | Price | Quantity | Total | |

| WIB6 - Welded Inertia Base | ||||||||||

| WIB6 24X48 | 24 | 48 | 6 | 135 | 550 | 685 | Inquire | |||

| WIB6 24X60 | 24 | 60 | 6 | 155 | 700 | 855 | Inquire | |||

| WIB6 30X60 | 30 | 60 | 6 | 170 | 880 | 1,050 | Inquire | |||

| WIB6 36X60 | 36 | 60 | 6 | 190 | 1,050 | 1,240 | Inquire | |||

| WIB6 48X72 | 48 | 72 | 6 | 250 | 1,700 | 1,950 | Inquire | |||

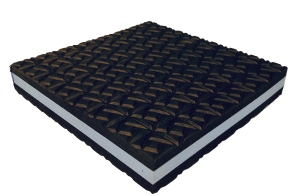

What is the concrete filled inertia base?

Inertia bases for the mechanical equipment have to be filled with concrete most of the times to provide structural integrity and stability of the equipment as well as to distribute the heavy load of the components sitting on the base. This type of foundation provides stability while reducing or completely eliminating the vibrations.

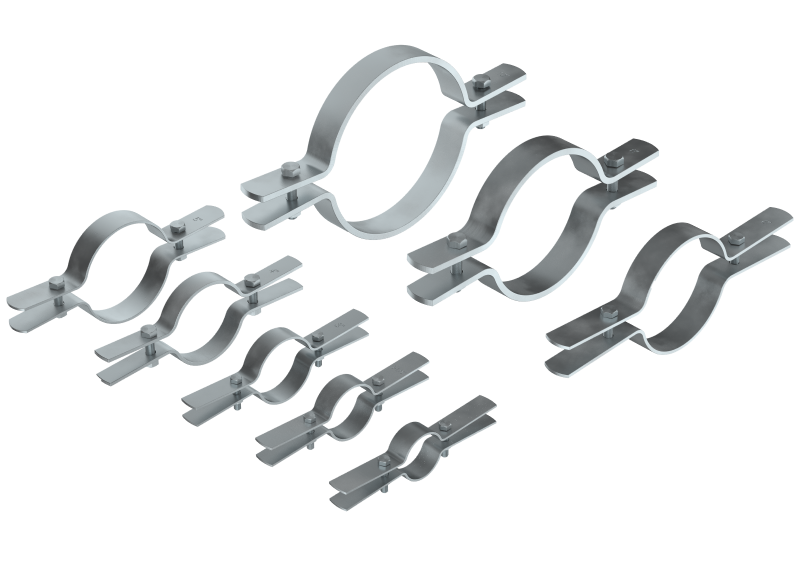

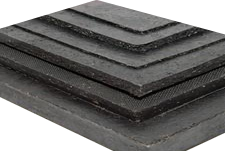

Inertia base itself is usually made of steel with threaded rods or mesh inside it to eliminate concrete cracking and metal disintegration. This way it offers strength and mass inimizing the transmission of noise and movement to nearby structures at the same time.

Concrete-filled inertia bases are commonly used in applications where precise alignment and minimal movement are crucial for the proper operation and longevity of the machinery. They help to maintain the integrity of the equipment and ensure reliable performance over time.

What is the weight of the inertia base?

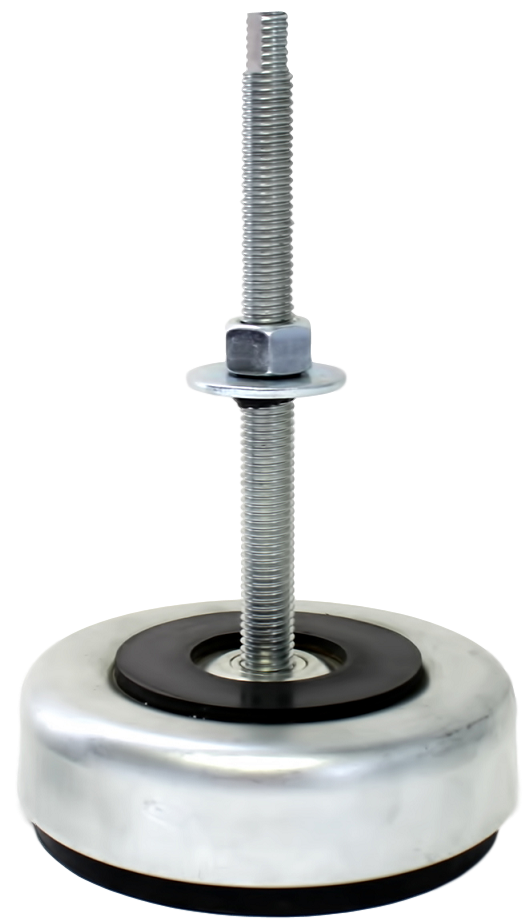

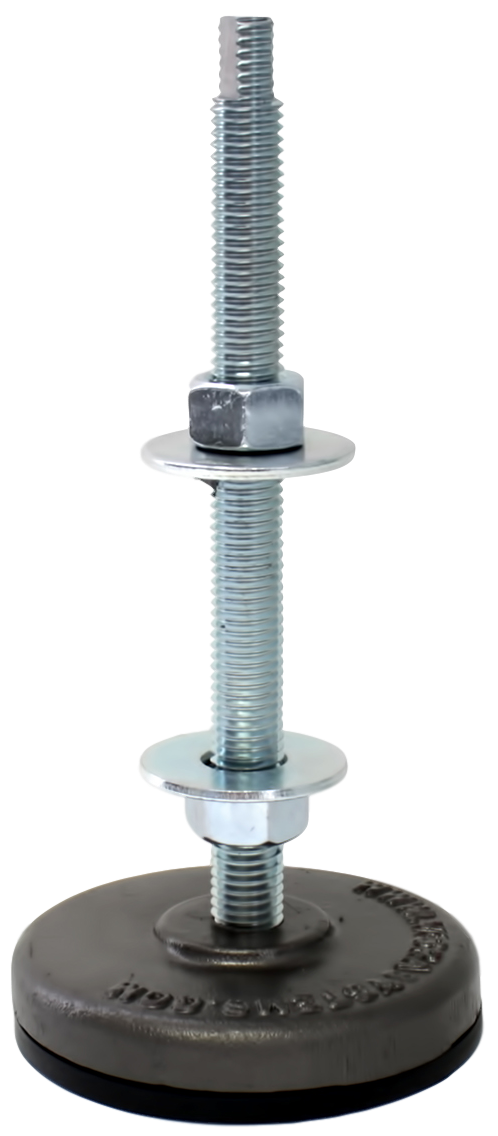

Inertia base weight depends on the size of the inertia base itself, the height of the channels that inertia base is made of and the mechanical equipment that will be sitting on it. Weight of the poured concrete will be calculated based on the cubic feet of the inertia base size as well. All calculations on the bases and concrete load are avalable on Vibrasystems Inc website. While choosing the vibration isolators that are going under the inertia base, customer need to take these weight into consideration plus add the weight of the equipment and divide the total by the number of spring vibration isolators that need to support the base.

What sizes are inertia bases come with?

Vibrasystems inc carries most popular inertia base sizes with 6" high base channel in stock. These sizes can accomodate the majority of the standard equipment/bsed mounted pumps installed in the mechnical rooms. We also can produce any custom made inertia base size and run the calculation with recommended height, width and length based on the customers' specs.

Notes:

a) Custom sizes can be supplied upon request.

b) Concrete’s weight - assuming minimum 3,000 psi strength and density of 150 lb/cub.ft (concrete by others).

c) Please see submittal drawing and Installation Instructions for more information.

Benefits:

Reduced Noise: Combining an inertia base with vibration isolation can significantly reduce noise generated by vibrations, improving the working environment.

Equipment Longevity: The reduction in transmitted vibrations can extend the lifespan of machinery and equipment by minimizing wear and tear.

Structural Protection: It protects the integrity of the surrounding structures by preventing vibrations from causing damage.

Comfort: Inertia bases and vibration isolation techniques can enhance comfort for building occupants by minimizing perceptible vibrations.

Considerations:

Design and Engineering: Proper design, including mass calculation, vibration analysis, and selection of appropriate vibration isolation components, are essential for an effective solution.

Installation: Correct installation of the inertia base and vibration isolation components is crucial for achieving the desired results.

Inertia base with the combination of vibration isolators offers a comprehensive approach to controlling vibrations generated by machinery and equipment. Installing inertia base helps to minimize the transmission of vibration, reduce the risk of equipment failure, structural damages.

We apologise for the inconvenience but this product is currently unavailable online. Please contact us directly to place your order

Phone: 18005670785

Email: info@vibrasystems.com