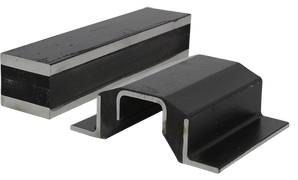

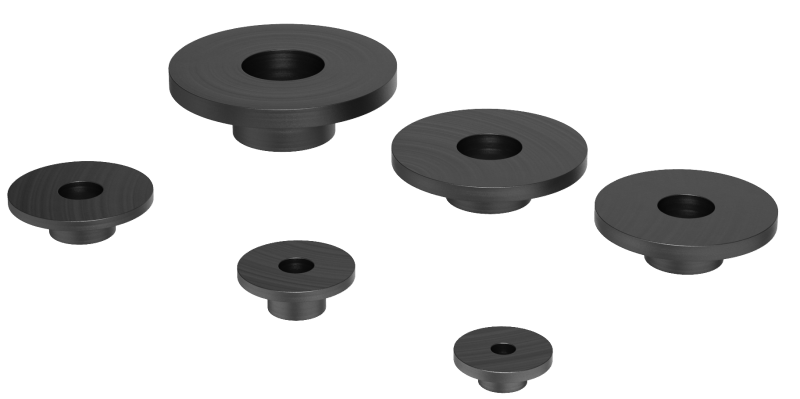

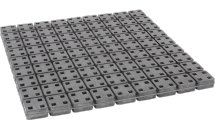

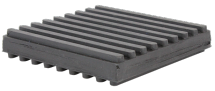

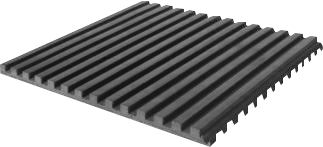

6.1ECRMP Easy Cut Pads

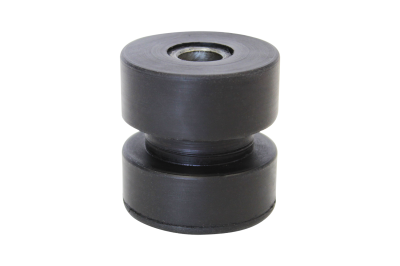

Vibrasystems Inc. ECRMP Rubber Pad is one of the most efficient and versatile antivibration Pads on the market.

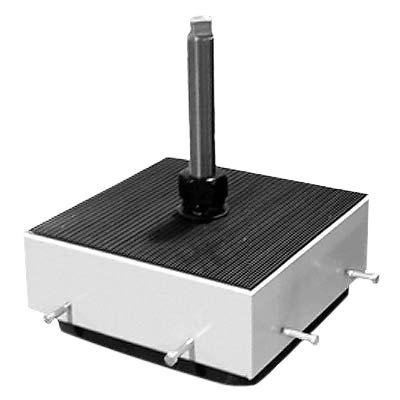

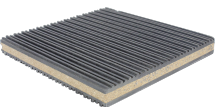

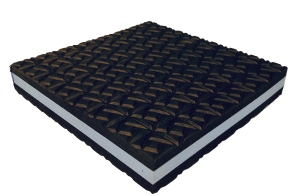

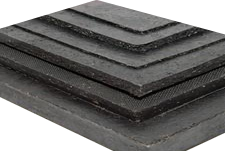

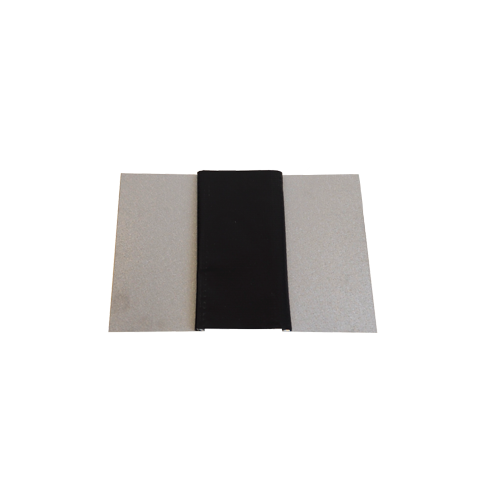

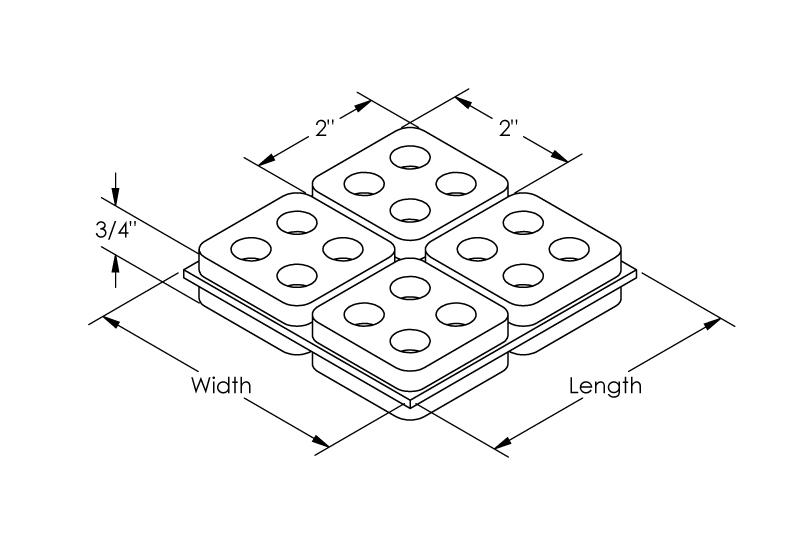

The anti-skid design with its suction cup of this vibraiton isolation pad eliminates the need for bolting down. The primary vibration absorption material is Neoprene that is excellent for installation for moderate oil resistance. The 2" squares are separated by a thin web that are very easy to cut through to the required size. For vibration dampening in applications where greater isolation efficiency is required. ECRMP Neoprene Pads could be glued with steel plates in the middle to create blocks/shims.

Recommended for:

The ECRMP Pad is suitable for applications where bolting is to be avoided and minor non-critical vibration conditions exist. It is also recommended for HVAC, motors, pumps, generators, air conditioning units, chillers, machine shop machines, etc.

Features:

| Model | Size | Shipping Weight (lbs) | Price | Quantity | Total | |

|---|---|---|---|---|---|---|

| ECRMP 0202 | 2" x 2" x 3/4" | 0.15 | $1.60 USD |

| ||

| ECRMP 0404 | 4" x 4" x 3/4" | 0.5 | $4.00 USD |

| ||

| ECRMP 0606 | 6"x 6" x 3/4" | 1 | - | - | Inquire | |

| ECRMP 1212 | 12" x 12" x 3/4" | 3.7 | - | - | Inquire | |

| ECRMP 1818 | 18" x 18" x 3/4" | 8 | - | - | Inquire |

NOTE:

- The standard size is 18" x 18". Cut sizes are also available.

- ECRMP Pads should be used in full squares (2" x 2").

- Working range: 50 to 120 psi.

- We can mold it from other types of rubber material based on the customer's specifications.

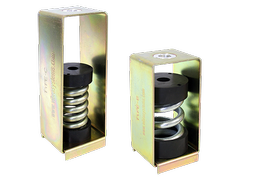

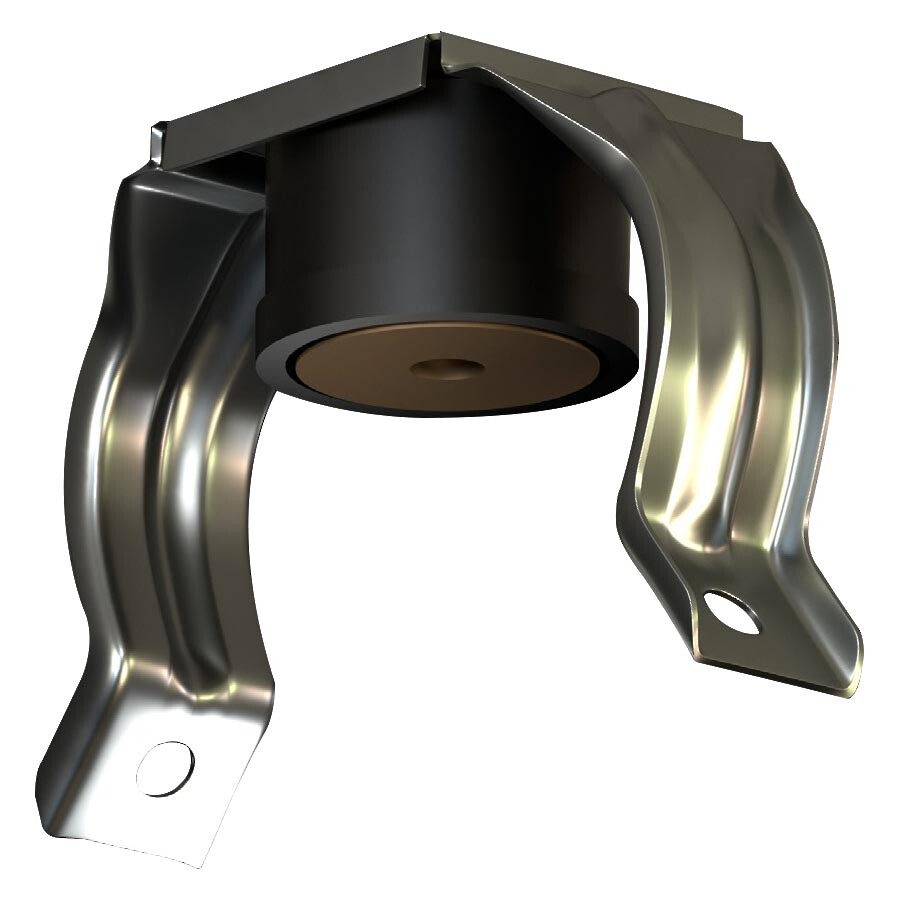

The installation of vibration isolation pads is an important step in reducing vibration and noise in various applications, such as HVAC (Heating, Ventilation, and Air Conditioning) systems, industrial equipment, and machinery. These pads are designed to absorb and dampen vibrations, which can extend the life of equipment and create a more comfortable environment. Here are the general steps for installing vibration isolation pads:

Installation steps:

Safety Precautions: Before starting the installation, make sure you have the appropriate safety gear, and if the equipment is electrical or hydraulic, disconnect the power supply or shut it down to ensure your safety.

Assessment: Determine the weight and dimensions of the equipment or machinery that will sit on the vibration isolation pads. This information will help you choose the right size and type of pads.

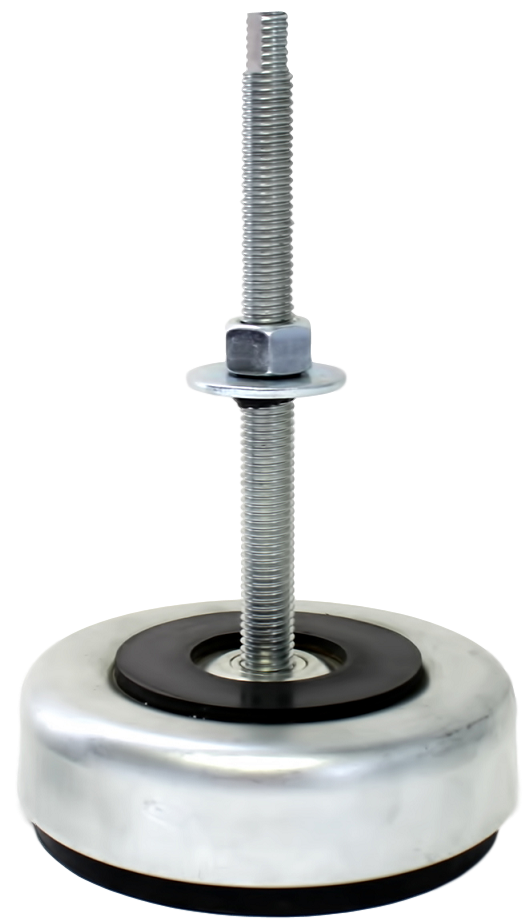

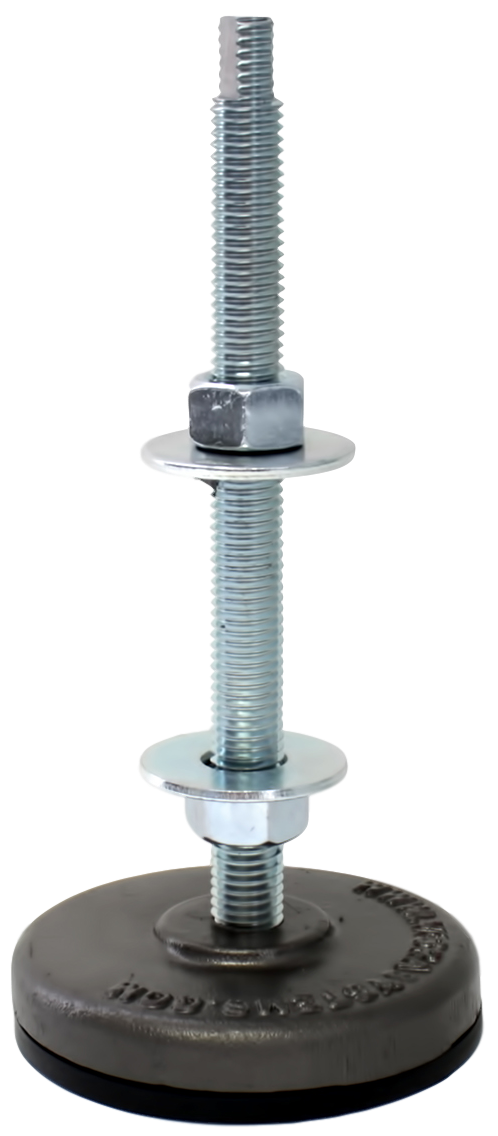

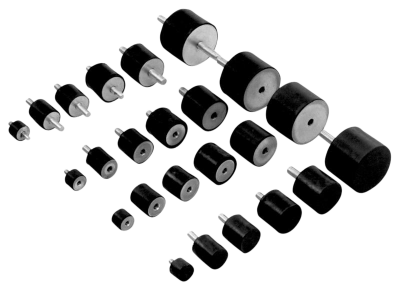

Select Suitable Pads: Choose vibration isolation pads that are designed to support the weight of your equipment. Pads come in various sizes and materials, such as rubber, neoprene, or cork-rubber composite. The choice depends on the application and the level of vibration isolation required.

Placement: Place the vibration isolation pads under the equipment or machinery in the desired location. Ensure that the surface you're placing the pads on is clean and level. If it's not level, use shims or other leveling methods to make it even.

Secure the Equipment: If the equipment has mounting brackets or feet, ensure that they are aligned with the holes or slots in the vibration isolation pads. If not, you may need to drill holes or create slots in the pads to accommodate the equipment's mounting points.

Bolt or Screw Down: Secure the equipment to the vibration isolation pads using bolts or screws. Make sure the pads are properly sandwiched between the equipment and the mounting surface.

Adjustment: Use a level to ensure that the equipment is level and balanced. If necessary, make adjustments to the pads or shims to achieve a level surface.

Reconnect Power: If you disconnected the power supply, reconnect it and test the equipment to ensure that it's functioning properly.

Regular Inspection: Periodically inspect the vibration isolation pads to ensure they are in good condition. Over time, pads may wear out and lose their effectiveness, so they may need to be replaced.

We apologise for the inconvenience but this product is currently unavailable online. Please contact us directly to place your order

Phone: 18005670785

Email: info@vibrasystems.com