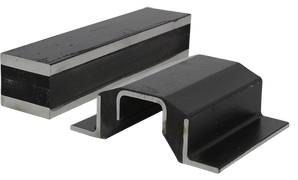

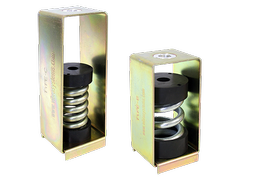

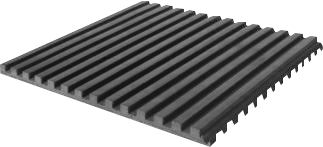

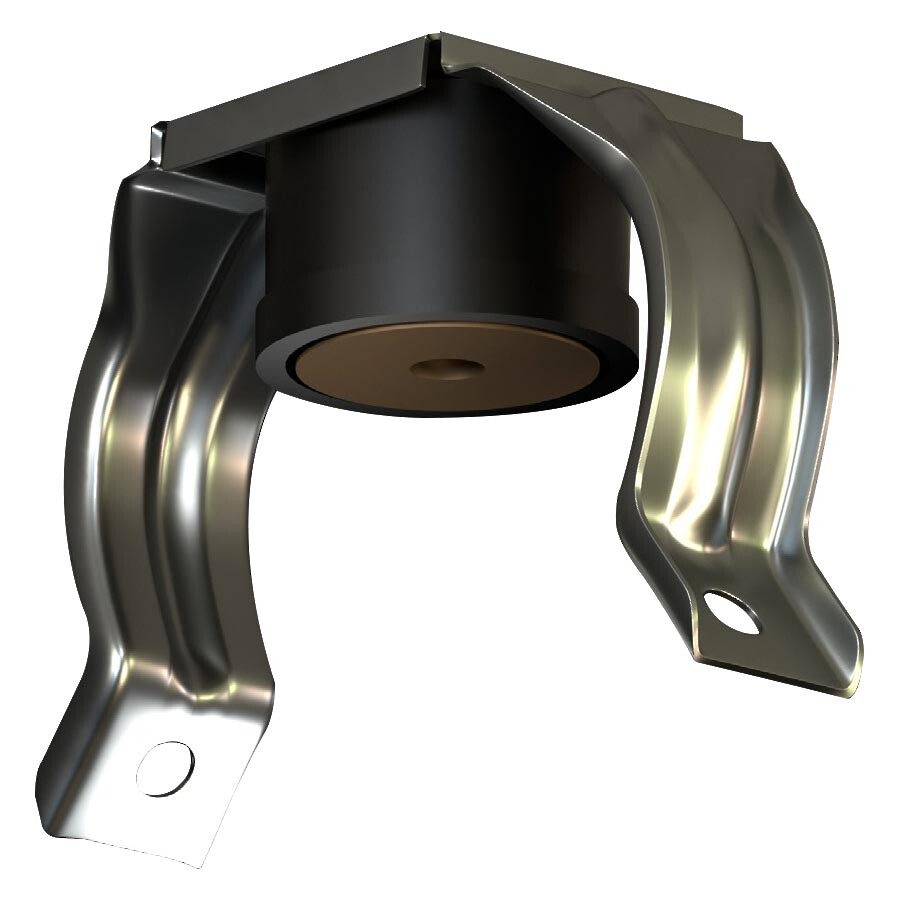

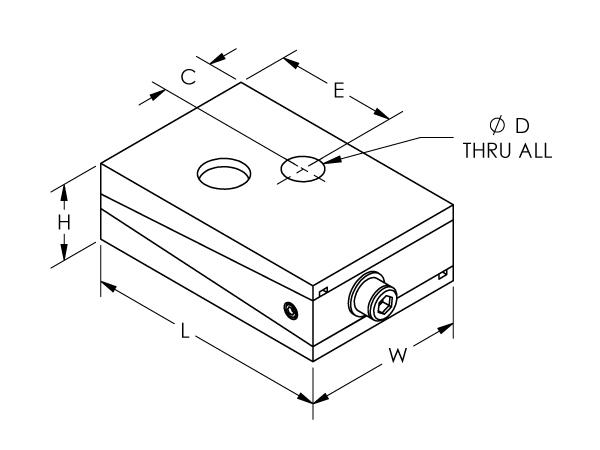

1.11Wedge Mounts

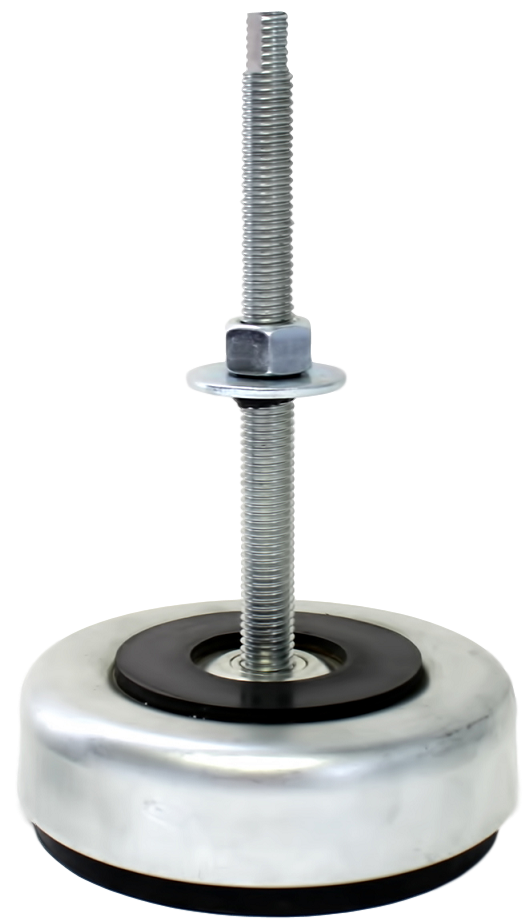

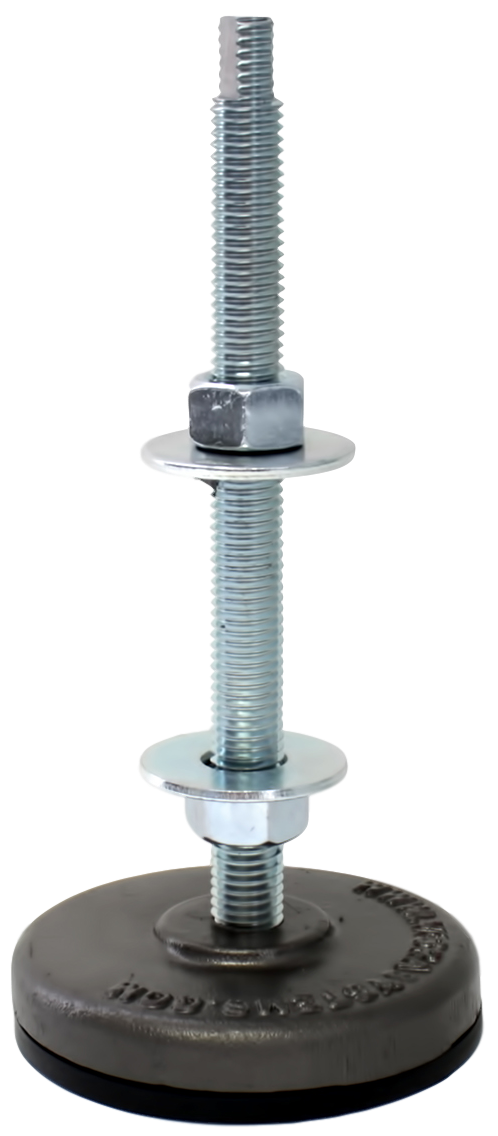

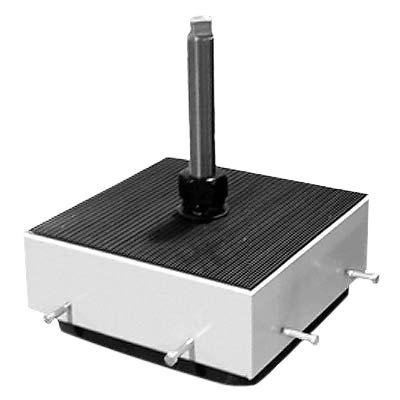

VWH mounts are designed for precise leveling of heavy industrial machinery such as injection mold machines, lathes with long beds, CNC machine centers, heavy platforms, etc.

These mounts achieve accurate leveling through three precision ground wedges. Wedges are guided and provide stable, accurate leveling under heavy load. Three machined wedges are held together by a horizontal adjusting bolt. A lock screw secures the mount in the leveled position. Keys in the sliding surfaces of the wedges ensure rigid mount construction. A special opening allows for bolting the machine to the floor.

Features:

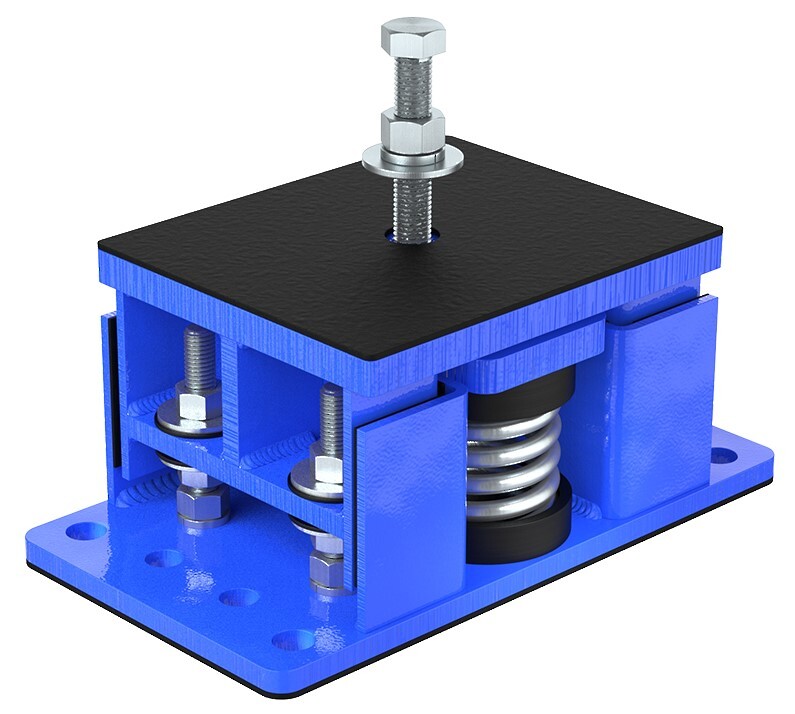

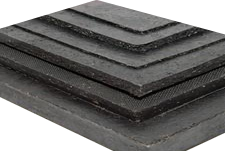

Mechanism: A wedge vibration isolator consists of two inclined surfaces, or wedges, that are used to support the load. These wedges create an angle between the load and the base, which allows the isolator to absorb and dissipate vibrational energy. When vibrations occur, the relative movement between the wedges generates friction, converting the kinetic energy of the vibrations into heat and reducing the transmission of vibrations to the connected structure.

Isolation Principle: The wedge design enables the isolator to be sensitive to vibrations in the vertical direction while providing stability against horizontal movements. The wedges create an internal frictional force that opposes the movement caused by vibrations, resulting in effective vibration isolation.

Design Considerations: When selecting and using wedge vibration isolators, it's important to consider factors such as load capacity, vibration frequency, amplituda of vibrations amongst others. Proper installation and adjustment are crucial to achieving optimal performance.

Limitations: While wedge isolators offer effective vertical vibration isolation, they may not provide as much isolation against horizontal movements or rotational vibrations. In applications where multi-axis isolation is required, other types of isolators might be more suitable.

Applications:

Precision Machinery: Wedge vibration isolators are commonly used in applications where high precision and stability are essential, such as optical equipment, laboratory instruments, and semiconductor manufacturing equipment.

Microelectronics: These isolators are suitable for isolating sensitive electronic devices and equipment from vibrations that could affect their performance.

Metrology: Wedge isolators find use in metrology applications, where accurate measurements are required and any external vibrations can introduce errors.

Research Facilities: Laboratories and research facilities that require stable environments for experiments and testing can benefit from wedge vibration isolators.

Medical Equipment: Some medical devices, like microscopes and imaging equipment, need to be isolated from vibrations to ensure accurate diagnoses and procedures.

We apologise for the inconvenience but this product is currently unavailable online. Please contact us directly to place your order

Phone: 18005670785

Email: info@vibrasystems.com