Importance of AntiVibration Pads and Their Applications

Any machinery or industrial part which exudes high-frequency vibration has the potential to cause output errors as well as damage the equipment in the long run. For high-precision machines, these vibrations need to be dampened to a certain extent for optimal operation. To achieve this, anti vibration pads are used in a wide variety of industries.

What are anti vibration pads?

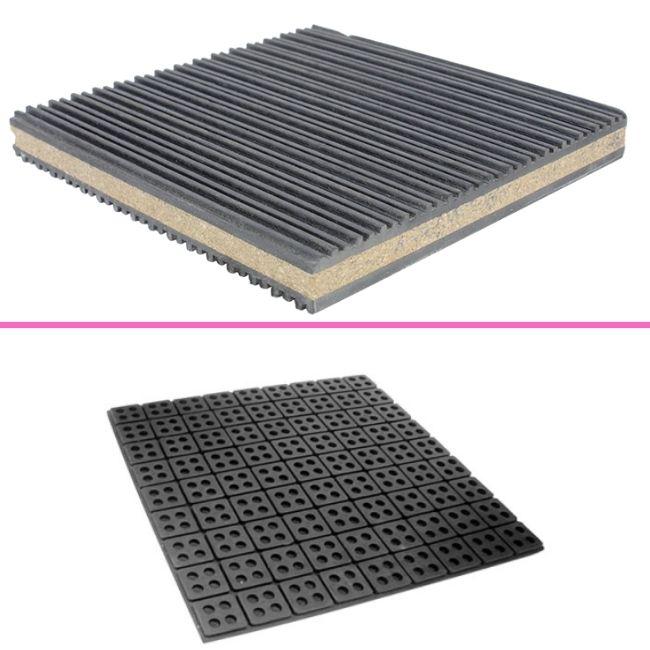

Machines with several moving parts release significant vibrational energy along with structural noise. Anti vibration pads effectively dampen or isolate these high-frequency vibrations to decrease instability and noise. Made of high-grade rubber, these pads have extreme visco-elastic properties that allow them to absorb and dissipate energy without incurring any damage to their structural integrity. The use of rubber as a primary ingredient reduces their cost of manufacturing, thus anti vibration pads are an extremely efficient and cost-effective solution to achieve dampening.

Industrial Applications of Anti Vibration Pads

In the industrial sector, high-grade rubber pads can effectively be used to isolate excess vibrations in heavy machinery. The pads are most efficient where no bolting is required, such as generators, transformers and air conditioning units.

Moreover, they can operate smoothly in a wide temperature range that approximately spans from -40 F to 158 F. Thus, they can be installed on machines that operate in these extreme temperatures. Finally, these cost-effective isolation units can be customized on the basis of thickness or application.

Vibrasystems offers anti vibration pads in many different iterations such as ECRMP Easy Cut Pads with anti-skid properties, BPXP Load Bearing Pads made of fiber-reinforced rubber, CRMP Cork/Neoprene Pads that use cork and opposing ribbed pads and, much more.

Browse our website for a wide range of vibration isolation products, or contact us for custom solutions regarding vibration and optimum load distribution.