Selecting Correct Vibration Isolator

Vibrations can be harmful in many circumstances, particularly in the scope of engineered systems and construction spaces. They can propagate through mechanical waves, and as a result vibration isolation methods have been created to prevent vibrations from occurring, and absorb or dampen those mechanical waves.

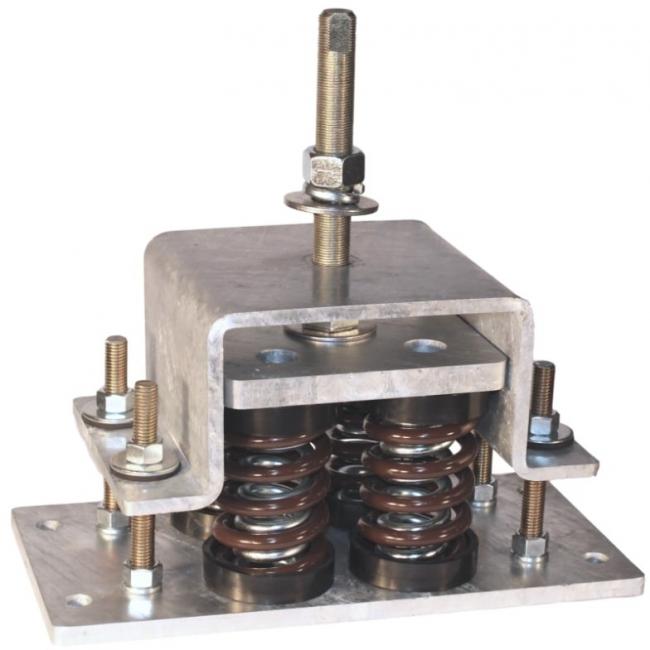

Vibration isolation pads, spring mounts and hangers all contribute to the stabilization and support of heavy loads and equipment.

There are two main factors to look out for when selecting the right part:

Deflection

Deflection is the degree to which a vibration isolator is displaced under a load. This determines how well the isolator will work. More deflection means less vibration transmission. These three different types of isolators yield different results:

- Vibration isolation pads deflect the least, and can be efficient while installed under free standing equipment with operating frequencies higher than 1500 rpm

- Neoprene vibration isolation mounts work well if mechanical equipment has to be bolted to the floor with operating frequencies larger than 1200 rpm

- Spring isolators have the greatest deflection for maximum vibration reduction and are recommended to be installed in the areas where lower frequencies are present

Location

Where your equipment is located within the building is the main factor of which type of isolation method to select, whether that’s neoprene mounts or springs.

- Neoprene mountings are suited for underneath equipment on very stiff support structures such as a ground supported concrete slab.

- Spring are necessary for the upper building level, which is more susceptible to vibrations

If your business is looking for isolation pads, spring mounts or hangers, Vibrasystems Inc. has an experienced in-house team of engineers that can find the right fit for your project. Contact us today to learn about our custom engineering solutions!